Automatic Station for Hinge hole

Drilling table designed to automatically perform the hinge holes on the sash.

The table is equipped with four pneumatic clamps - two horizontal and two vertical - for a safe and precise block and a bidirectional drilling head with mechanical positioning; the holes are made on the reference of the external edge of the door.

HDHS is the ideal solution to make drilling fast and easy for fixing the hinges. Immediately after welding: it can replace the cooling table when positioned downstream of the welding machine.

5 Reasons to choose HDHS

Less labor: It automatically makes both the movement of the frame and the necessary holes.

More precision: Measurements are made automatically based on the reference of the external edge of the door.

Spaces optimization: Replacing the cooling table of the welding machine allows production lines with reduced dimensions.

User friendly: Simple and immediate management and easy configuration of operating parameters.

Bidirectional drilling head: Mechanically positioned and automatic drilling depth adjuster.

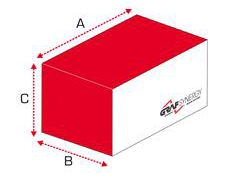

Dimensions

-

Length (A)

4.000 mm -

Width (B)

3.500 mm -

Height (C)

1.400 mm -

Weight

1.200 Kg

Details

-

Installed power

2 Kw -

Supply

400 V -

Air consumption per cycle

10 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Frames produced/8h

Production of the welding machine

Workable Dimensions

Maximum

-

Heigth

2.800 mm -

Width

1.000 mm

Minimum

-

Heigth

370 mm -

Width

300 mm

On request the machine can be equipped with:

- Bidirectional head positioning on controlled axis.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA