GRAF Synergy turns 14, but already has over 40 years of experience!

To understand how it is possible…let’s proceed in order.

The 30th November is not just any date for the PVC world processing is in fact the day when ,in 2009, was signed the foundation of GRAF Synergy, the company that has pushed standards higher in the production of PVC windows and doors.

It all begins at the end of seventies, in a garage of the province of Modena, Emilia Romagna, the heart of Italian mechanical excellence. Here four enterprising brothers follow the footsteps of their electrician father and transform the activity in a craft company. From this “adventure” starts the first spark of that it becomes then GRAF Synergy.

In 1994 the society takes shape, giving itself as a name the acronym resulting from the initials of the surnames of the partners who had joined the company in the meantime: thus GRAF was born.

Specialised in services for the manuifacturing world, GRAF Srl stands out from the start in the electronics and information technology. During nineties the company cooperates very closely with its customers to develop solutions that simplified the control and functioning of the machines, realising in the practice the concept of mechatronics, an interdisciplinary field which integrates mechanics, electronics and information technology to design, create and managing automated and intelligent systems.

The crisis of 2008 marks the turning point. If from one side hits very hard some GRAF customers including also manufacturers of window machinery, from the other side becomes the starting point for a decisive company transformation. The crisis also poses difficulties to GRAF, but this unfavourable condition will instead be experienced as an opportunity: in 2009 GRAF Synergy was born which, on closer inspection, brings together all the previous professional skills related to window manufacturing machines. GRAF moves from supplier partner to full-fledged machine manufacturer, paving the way for a new chapter of innovation in the sector.

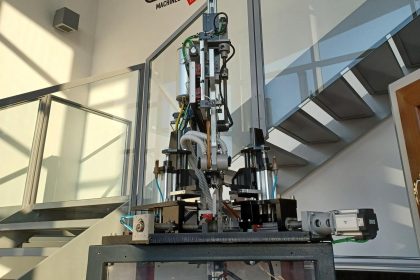

2012 represents a new turning point for GRAF Synergy, epochal not only for the company itself but also for the entire windows and doors sector: a technology until then unknown for the welding of PVC windows is introduced on the market, revolutionary enough to earn a patent. The welding machine SL4FF sees the light which in few time would have transformed disruptively the market leading GRAF to becoming the world reference of the PVC windows and doors welding. In the meantime GRAF Synergy continues with the production of welding lines and conventional machineries with a high level of quality and reliability, that remain a precious source of experience and experimentation for all the company production.

The path to success was not so easy. GRAF Synergy dedicated thousands of hours to the development of SL4FF welding machine, activating close partnerships with customers, suppliers and universities. The result of this commitment has been the patent of that new technology named “V-Perfect”, a guarantee of aesthetics and robustness. The evolutions continue then over time, giving life to the following SL4FF EVO RS, SL4FF EVO WOOD, SL6/8FF EVO, SL2FF EVO and more to come creating what will later become the mission and vision of GRAF: the constant approach towards innovation and improvement.

To realise all this GRAF Synergy makes use of an internal research center highly specialised that is the forge of ideas from which also derives the patent of V-Perfect®technology. It’s precisely thanks to the research and development that the aesthetic perfection level guaranteed by the machineries of V-Perfect® line can be applied on each type of PVC profile. From those coated with films or foils which reproduce the aesthetic of wood and aluminium, to the PVC profiles and real aluminium, to those in painted PVC.

The growth is overpowering and already in 2018 GRAF Synergy reaches the milestone of doubling its production facilities.

2020 marks a further milestone with the definition of Fast Forward Plant service, whose studies began in 2016, a design formula customised with new specific machines automates the factory, guaranteeing from one side the saving time and resources and from the other the increase of production. Turnkey.

Now, after many years after its foundation, GRAF Synergy is a solid and structured reality with approximately 42.000 square metres of production areas, 3000 square metres of offices and laboratories, present in over 60 countries in the world and with a subsidiary company in Canada. International vocation is now the company’s hallmark.

Passion, dedication, sacrifice and obstinacy transformed that garage of the seventies in the industry of today: here’s why for GRAF Synergy the 30th November 2023 is the 14th anniversary of the foundation but it also means celebrating over 40 years of experience and work.

GRAF Synergy transformed its challenged in opportunities: discover what can do for you and your windows and doors company, contact now GRAF Synergy!

Pills of a story that starts from afar:

- – 1990 – First 2-head inline welding machine

- – 1994 – First computerised cut-off machine

- – 1999 – First cutting centre

- – 2004 – First complete welding line

- – 2009 – GRAF Synergy was established

- – 2012 – First 4-head welding machine “without cleaning” with V-Perfect technology

- – 2014 – Automation of the entire windows and doors production process

- – 2015 – Division dedicated to process logistics

- – 2016 – Start of study and production of machines complementary to the vision of the automated factory

- – 2017 – First automatic hardware assembly bench with a cycle of less than 60 seconds

- – 2018 – Doubling of production facilities

- – 2019 – First cutting and machining centres for iron reinforcements with Plasma technology

- – 2020 – Fast Forward Plant (FFP) service is born

- – 2022 – Headquarters in Canada of the parent company GRAF Industries

- – 2023 – V-Perfect ‘no-clean’ welding machine number 900 sold

- – 2023 – Conni, system for joining iron restbar is born.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA