GRAF Synergy, well-known and appreciated for the production of PVC window and door machinery, repository of the exclusive V-Perfect patent, which allows the perfect welding of corners without curb and without the need for touching up or cleaning, will be among the undisputed protagonists of the next FENSTERBAU FRONTALE, scheduled from 19 to 22 March in Nuremberg.

The company, based in Nonantola (MO), will bring several world premiere novelties to this important event.

At the GRAF Synergy stand, a veritable “technology square” of over 600 square metres, it will be possible to see and touch for the first time innovative machines and technologies that will once again revolutionise the PVC window and door manufacturing sector, as happened in the recent past with the V-Perfect patent.

Here are some brief previews:

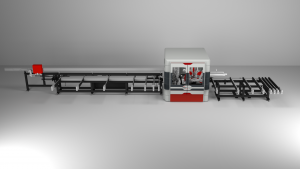

Fab Cut 3B RS: CNC cutting and machining centre with multiple controlled axes dedicated to window and door manufacturers who require even higher productivity levels, up to 500 frames/8h, depending on the machining operations, type of profile used and machine configuration.

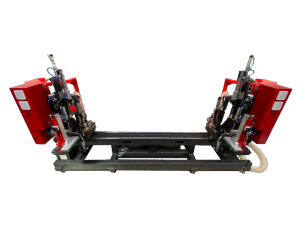

Faz IV: hardware assembly bench designed and built to perform automated assembly and screwing of hardware on PVC window and door sashes with a very high execution speed, capable of producing a finished sash every 50 seconds or so, depending on the processing, type of profile used and machine configuration.

SL8FF TR RS: the first and only 8-head CNC welding machine in the world that completely eliminates the welding curb from the corner, allowing PVC windows to be produced with uniform quality and superior aesthetics. A natural evolution of the 4-head SL4-FF Evo, thanks to the 4 extra heads it allows simultaneous welding of the 4 corners of a PVC frame complete with 2 transoms and, an absolute novelty, it is able to weld door sills independently with a high saving in time and labour. All without the need for subsequent cleaning or retouching.

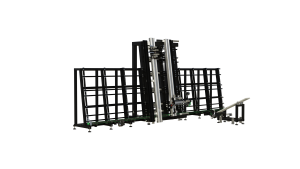

HDMV: CNC vertical bench for automatic drilling and assembly of hinges. It is the ideal solution for fully automated drilling and assembly of hinges: the bench is prepared for integration into an automated window production line and offers the possibility of mounting hinges even on intermediate mullions.

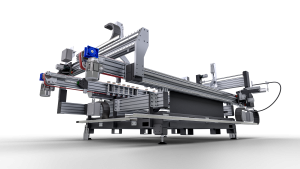

GBA 200: controlled-axis cutting centre for cutting PVC glazing beads, it is an automated system that allows glazing beads to be cut very quickly and automatically. Due to the high degree of automation, operator intervention is only required for loading the glazing beads and picking up the finished parts. The gripping system has been designed to tension the glazing bead longitudinally to avoid vibrations and bending during cutting. It also allows incredible flexibility in the use of new profiles, which are only to be added in the programming without the need to intervene on the gripping countershims.

SHUTTLE: an essential element in the automation of plant logistics, it is designed to automate the loading, handling and unloading of workpieces; thanks to it, it is possible to route and sort boards to and from any motorised structure and/or welding machine. The machine is part of GRAF Synergy’s FFP – Fast Forward Plant strategy, the integrated solution for customised, turnkey automation of the flow of workpieces, coordinating with time the movements within the plant to achieve a high operating speed and a clear reduction in both labour costs and damage to finished products.

Lastly, 2 new technologies will be unveiled in a world premiere, intended to talk about them the entire window and door industry, and not only:

Steel Cut – CONNIE: revolutionary blade cutting centre for steel reinforcements of PVC window profiles combined with a new module for welding the metal blanks of internal reinforcements to PVC profiles. It exploits a totally innovative approach to eliminate the waste of metal blanks, which would otherwise be destined for disposal and recovery as metal scrap. It offers window and door manufacturers concrete advantages not previously possible, both from an environmental and economic sustainability point of view.

PVC PRINTER: the GRAF Group has succeeded in being the first to develop an innovative technology capable of printing PVC on a wide variety of surfaces, from windows to the largest surfaces, making it possible to obtain three-dimensional prints and opening up new, hitherto unexplored aesthetic and expressive languages, made up not only of colour, but also of relief shapes and materiality. Plays of light and shadow, tactile effects, shapes, drawings, relief writing become the characteristics of the new and unique technology born in GRAF, applicable to many sectors, from design to industry, from furniture to architecture.

This year more than ever, GRAF Synergy is proud to open the doors of its world to all industry insiders and design and furniture enthusiasts: we look forward to seeing you from 19th to 22nd March at FENSTERBAU FRONTALE, Hall 3, booth 3-315.

Not least, to confirm 2024 as a year of great value for GRAF Synergy, the doors will open, and not only figuratively, on 18th April 2024 in Vaughan Ontario, Canada, for the grand opening of GRAF’s new larger headquarter, just few minutes from Toronto Airport: thanks to the new location customers in the Canadian and North American markets will have an SL4 FF EVO seamless welder in operation for demos on any profile required by the local market.

So many reasons to meet us, and find out what GRAF Synergy can do to maximise quality and productivity for all window manufacturers.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA