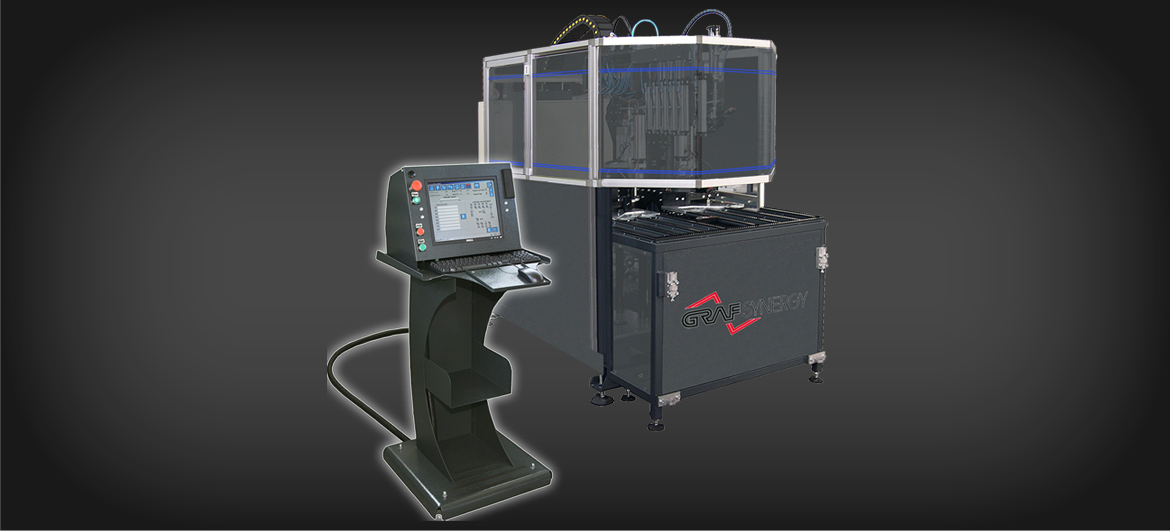

2 Axis Corner Cleaner Machine

2 axis controlled corner cleaner machine driven by linear motors which automatically carries out all the operations related to the external cleaning of the welding curb on Pvc profiles: centering, cleaning and release of the finish product.

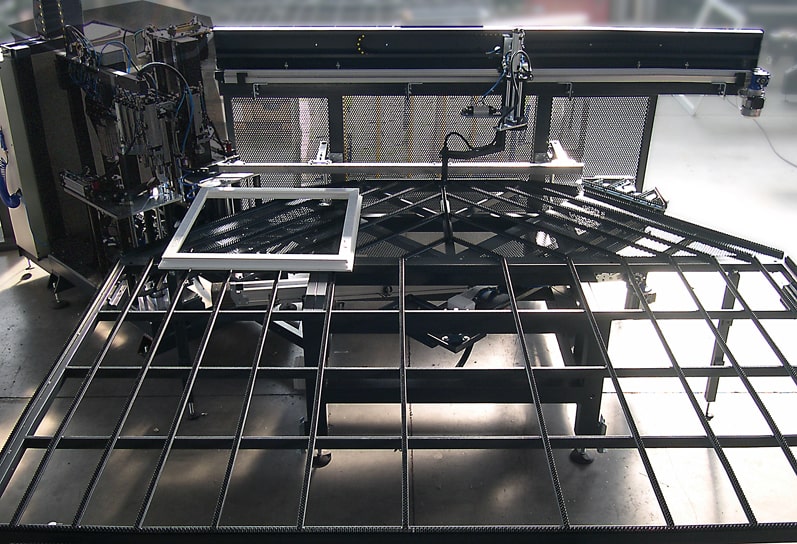

The system is proposed both in stand alone version and combined with an automatic piece rotation table; in this case you can put it connected in line with a welding machine 4 heads Quad.

The identification of of the square to be treated can take place after selection on the supplied computer or by quick reading with bar code (optional); If it is connected to a welding machine, it happens on input of datas passed by the same welding machine.

5 Reasons to choose the WP CNC 2

Axis drive with linear motors.

It solves any cleaning need: Widely configurable according to each specific profile.

User Friendly Technology: Simple creation of cleaning programs by uploading DXF files.

Acquisition of programs via USB port and TCP-IP network.

Ideal for the connection in line with 4 heads welding machines.

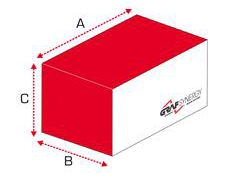

Dimensions

-

Length (A)

2.300 mm -

Width (B)

1.350 mm -

Height (C)

2.350 mm -

Weight

1.200 Kg

Details

-

Installed power

5.6 Kw -

Supply

400 V -

Air consumption per cycle

440 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Frames produced/8h*

Up to 240

* Stand Alone Vers.: Dependent on profile type and dimensions.

Frame Dimensions Cleanable (External)

-

Minimum*

340 x 400 mm -

Maximum

Manageable by operator

* Without rotation table.

Cleanable Profile Dimensions

Minimum

-

Height

40 mm -

Width

40 mm

Maximum

-

Height

180 mm -

Width

130 mm

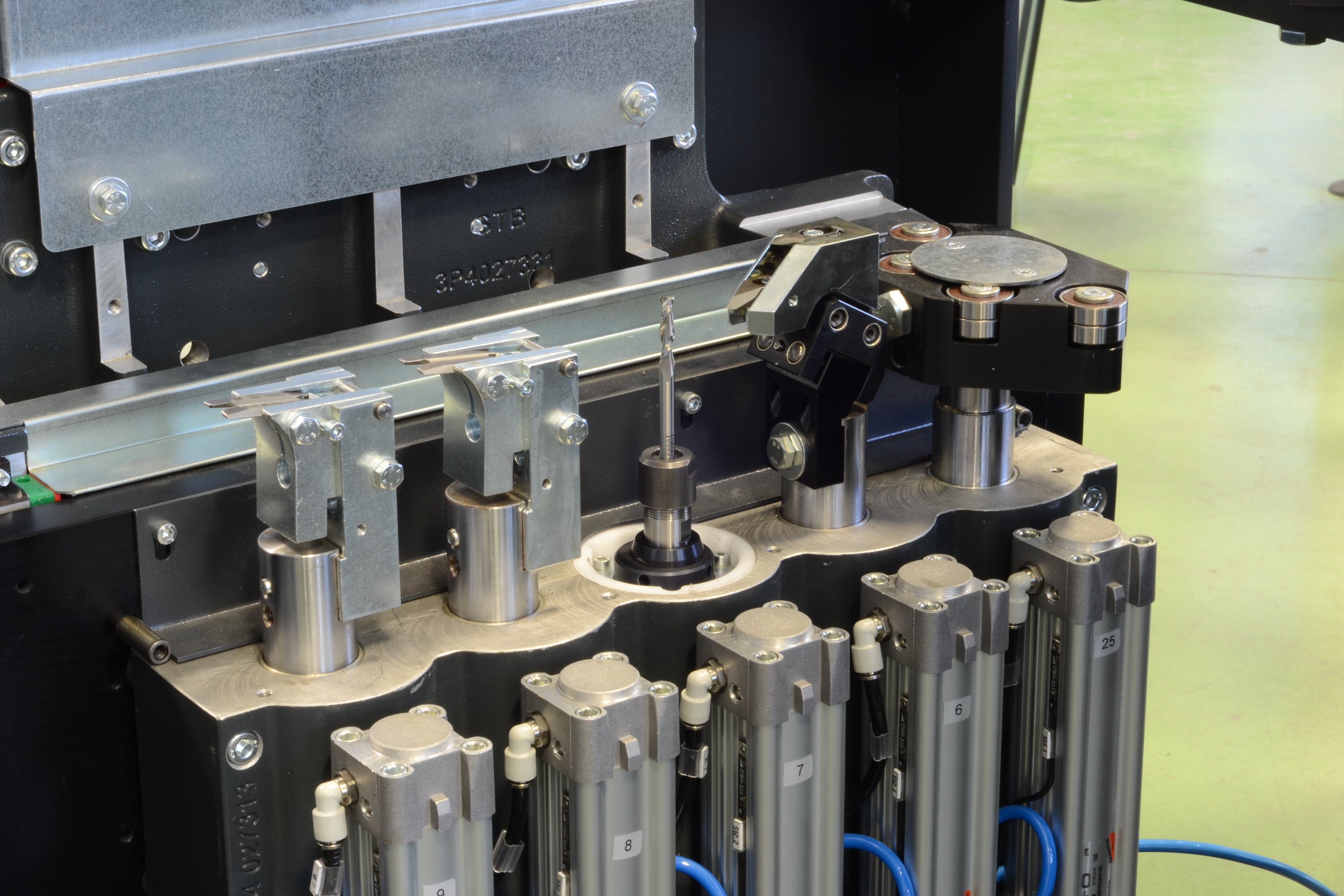

Structure

Cutter disc for external corner finishing.

Scratches for upper, lower removing and curved parts.

Cutters for the removal of specific areas.

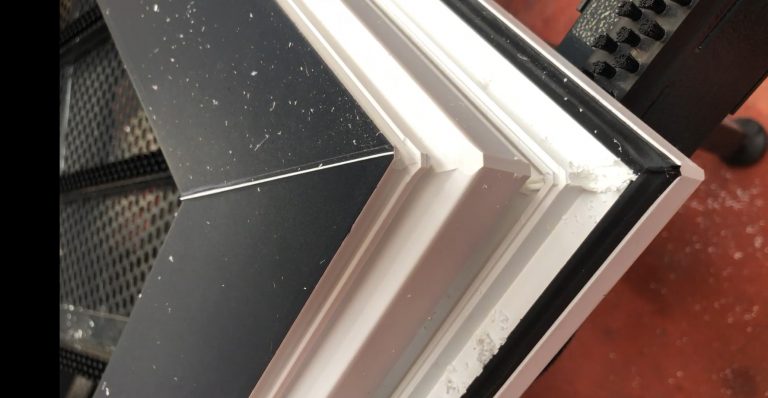

Machinings

- External cleaning of corner welded with blade.

- External and internal face cleaning grooved profile for white profiles.

- Internal and external seal milling.

- Internal corner cleaning of the glazing bead area.

- Cleaning of the internal corner of the profile stop area.

- Milling fins of the Reduced node.

On request the machine can be equipped with:

- Installation stand alone (manual loading table + Complete upper and lower protection).

- Upper grip rotation table (version Left or Right) – square max 2.500 x 2.500 mm.

- Lower grip rotation table (version Left or Right) – square max 2.500 x 2.500 mm.

- 2 inclination drill holder group.

- Upper tool handling unit.

- Lower tool handling unit.

- Self-centering tool holder group for classic and/or rounded internal corners.

- Upper drill handling unit.

- Lower drill handling unit.

- Self-centering tool holder group for internal corners 90° in pushing.

- Tool holder group for flat surfaces (white/colour).

- Profile recognition kit with barcode reader.

- Recognition of welded frames in combination at different heights (85 combinations).

Available Variants

Equipment with 4 controlled axes: Up to 320 Frames/8h* (requires 8.0 kW - 500 Nl/min)

* Depends on the profile type and size of the frame to be cleaned.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA