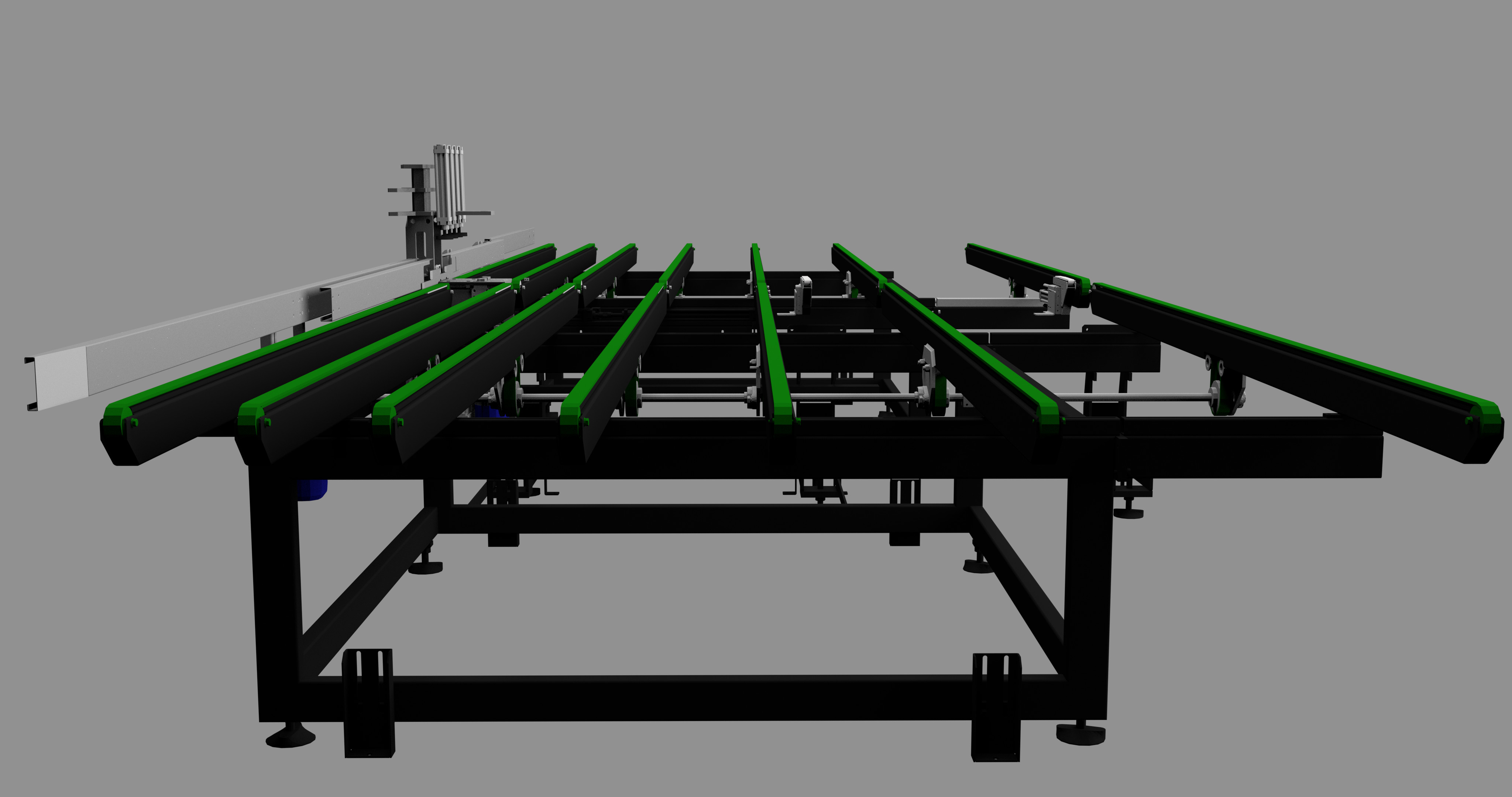

Corner milling automatic table for Sashes stulp

Automatic double-length table with High Speed central milling unit for the processing of the sash exchange side.

Designed to automatically mill the surplus material that there is in the 2 internal corners after the welding of the 3 door profiles together with the reduced door profile.

The table provides for gripping, centering and working the piece first on one corner and then - by repeating the cycle - on the other; The millings made on the basis of the reference of the automatic measurement of the reference plane and this allows to obtain precise and repetitive milling on all the profiles.

Particularly suitable for positioning in line with the SL4-FF Evo welding machine, the software allows the table to be controlled directly from the control panel of the latter, so that it can replace the cooling table.

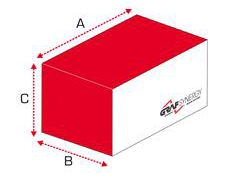

Dimensions

-

Length (A)

8.000 mm -

Width (B)

4.500 mm -

Height (C)

1.800 mm -

Weight

1.200 Kg

Details

-

Installed power

2.5 Kw -

Supply

400 V -

Air consumption per cycle

10 Nl/min -

Minimum Operating Pressure

6-8 bar -

Operators

1

Performance

-

Frames machined/8h

Manual Operation

Dimension of workable Square

-

Maximum

3.200 x 3.200 mm -

Minimum

400 x 400 mm

On request the machine can be equipped with:

Available Versions

Possibility to be equipped with 2 milling heads: Mod. ST2A.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA