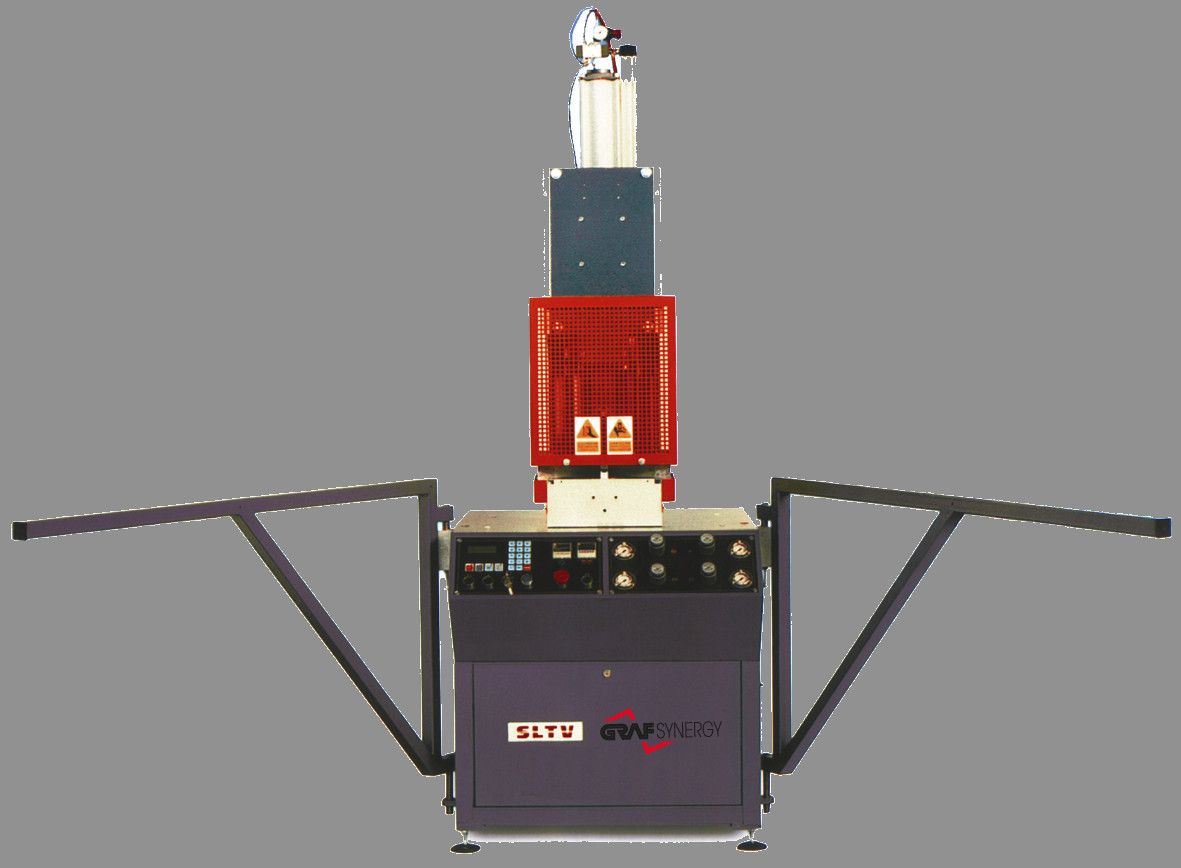

Universal Single Head Welding Machine

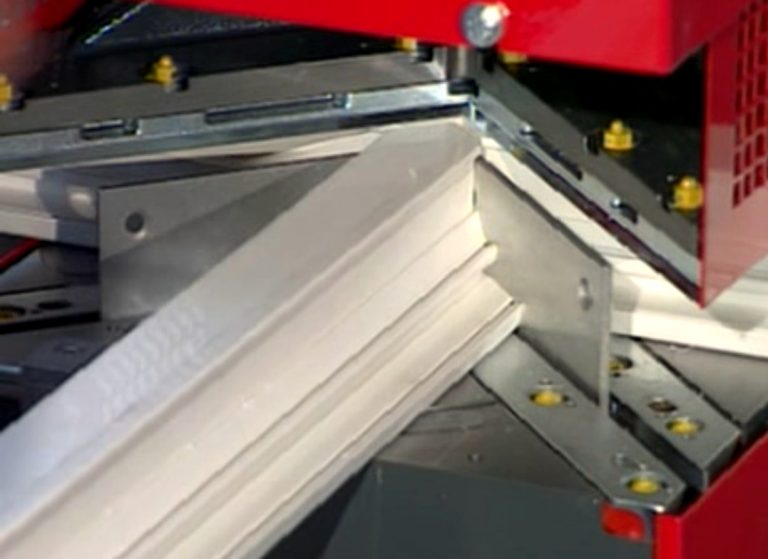

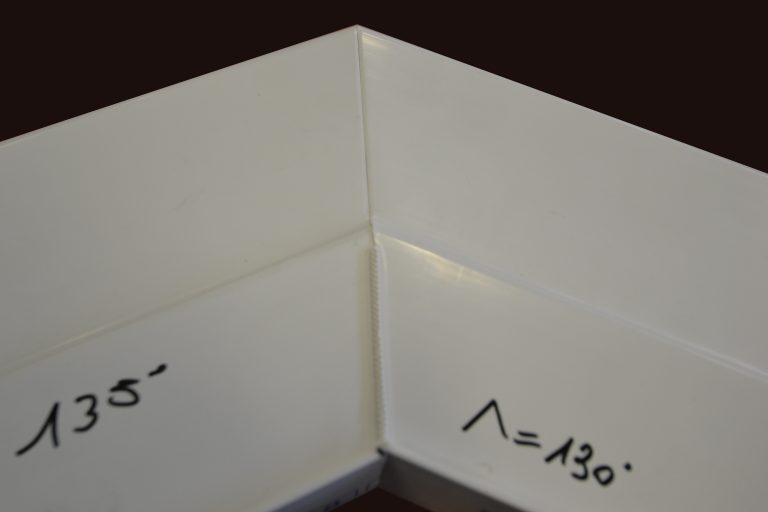

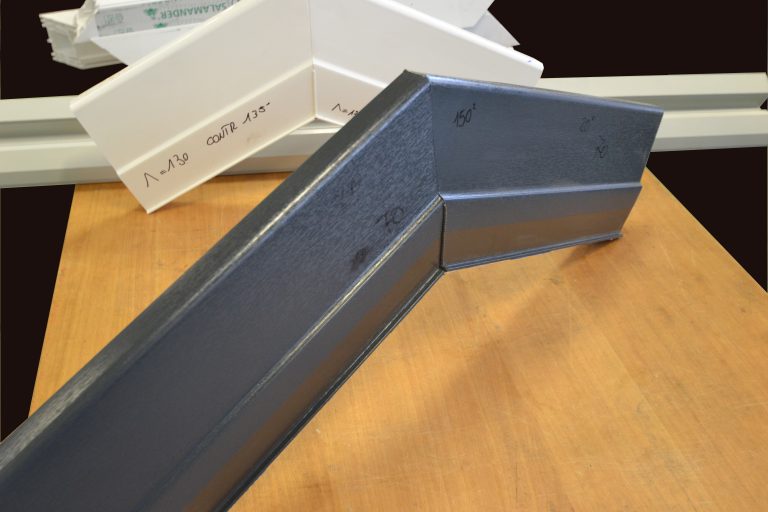

High precision welding machine capable of welding at "T", Cross or "H" (Notch Welding), on the ends and at variable angles between 35° and 180°.

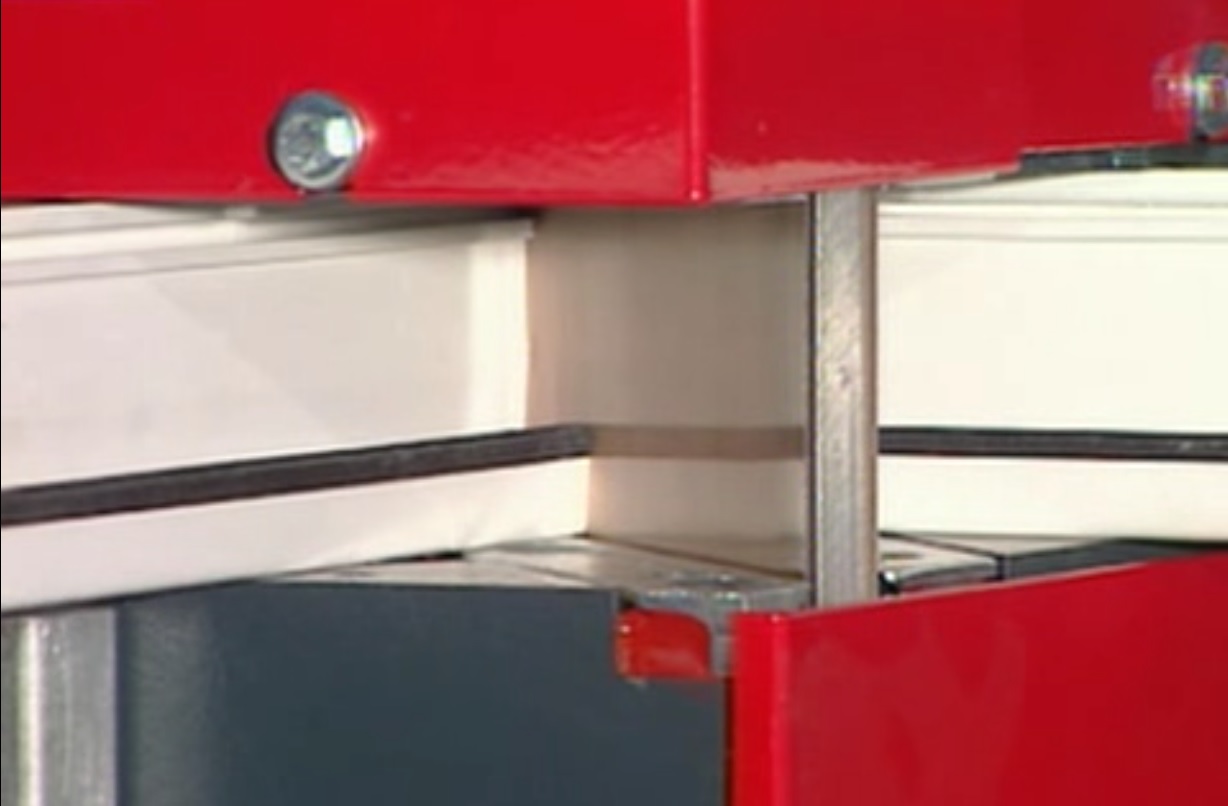

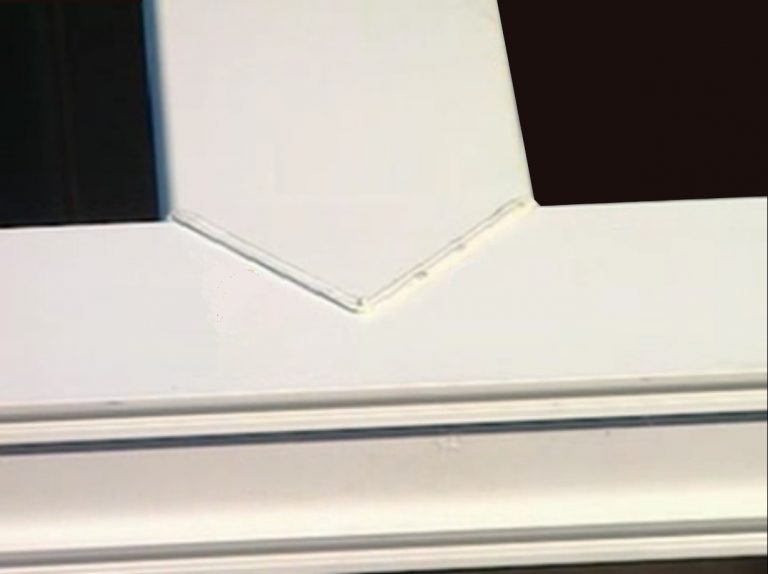

The welding of the transom is carried out on pointed and counter-piece cut profiles with relative "V" incision.

The unit allows the simple and quick adjustment of the different angles and an optimal control of the temperatures of the welding plates and weld bead limiting knives thanks to a reliable and safe electronic device.

5 Reasons to choose the SLTV

Superior quality welding: Obtaining and maintaining the exact angle setting measures.

Wide variability of weldable angle: between 35° and 180°.

Possibility to also weld “T”, Cross or “H” transoms (Notch Welding).

Control System: Measurement of welding times, checks for any anomalies and signals the need for intervention.

Quick replacement system for welding countershims.

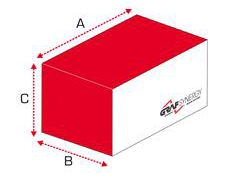

Dimensions

-

Length (A)

1.250 mm -

Width (B)

920 mm -

Height (C)

2.300 mm -

Weight

350 Kg

Details

-

Installed power

3.6 Kw -

Supply

230 V - Singlephase -

Air consumption per cycle

45 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Machined frames/8h

Manual Operation

Weldable Profile Dimensions

-

Height

40 ÷ 200 mm -

Width

40 ÷ 130 mm at 90°

Upon request the machine can be equipped with:

- Under measure countershims.

- Right-left horizontal/vertical clamps.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA