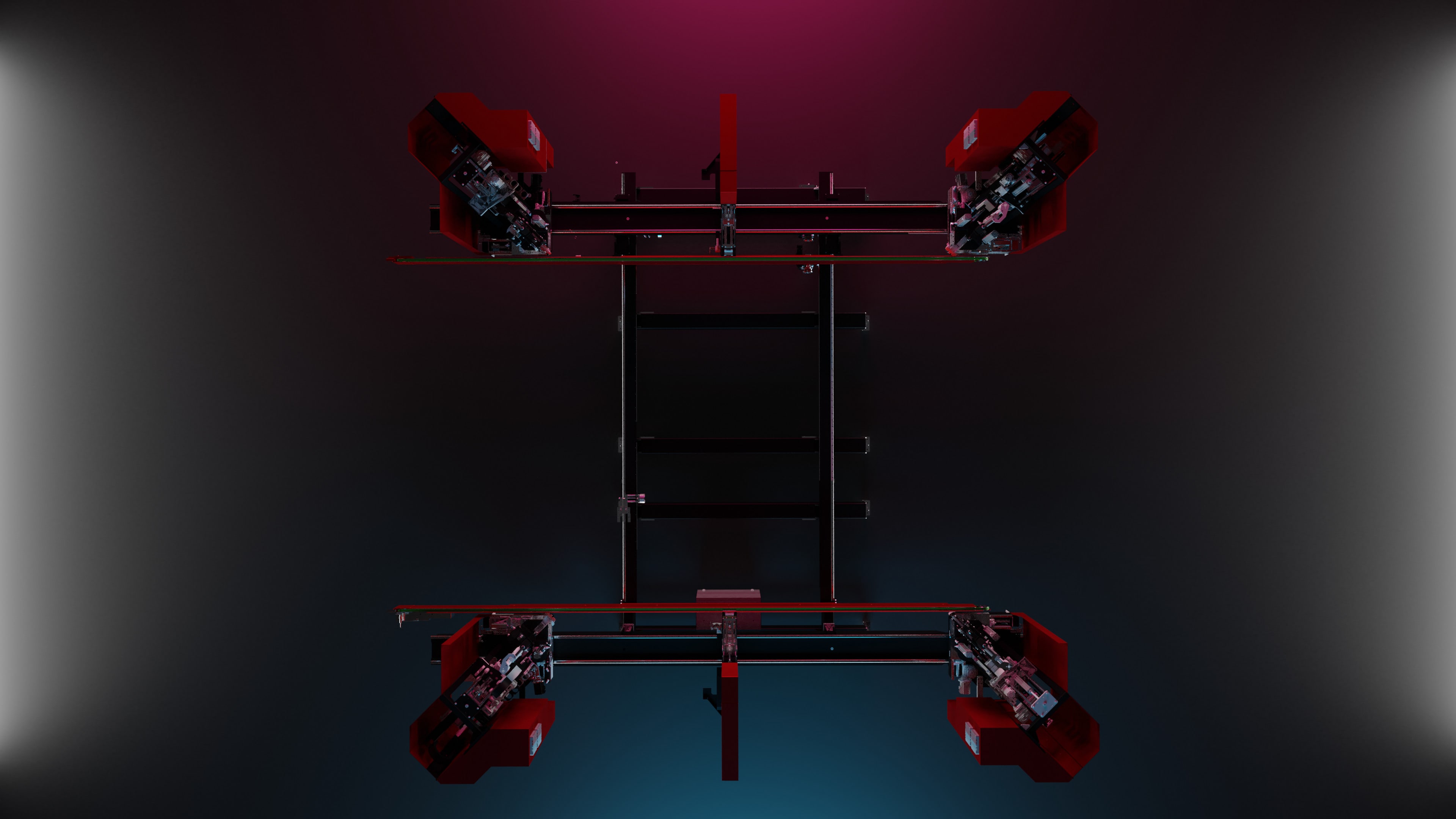

CNC 6-head Welding machine

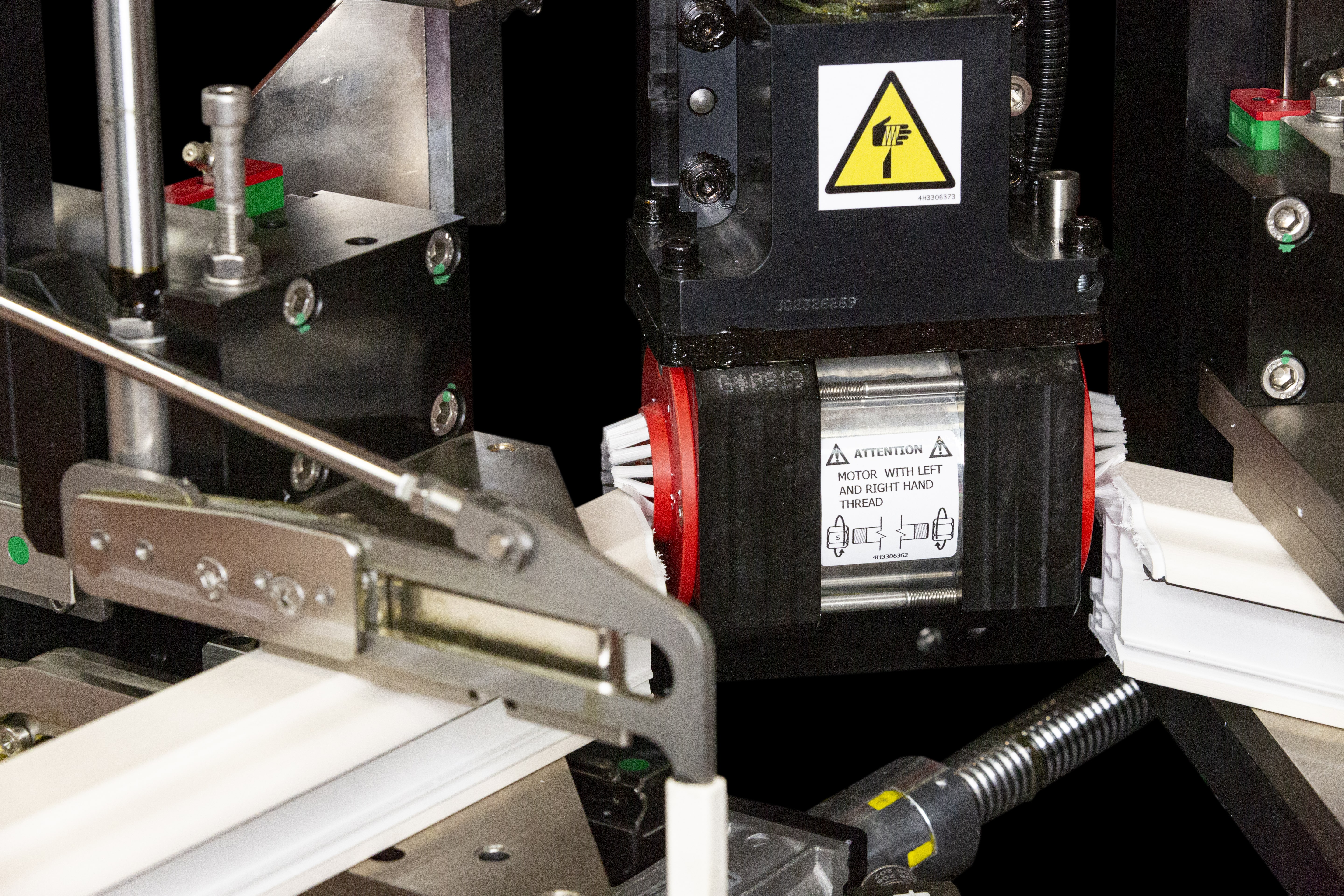

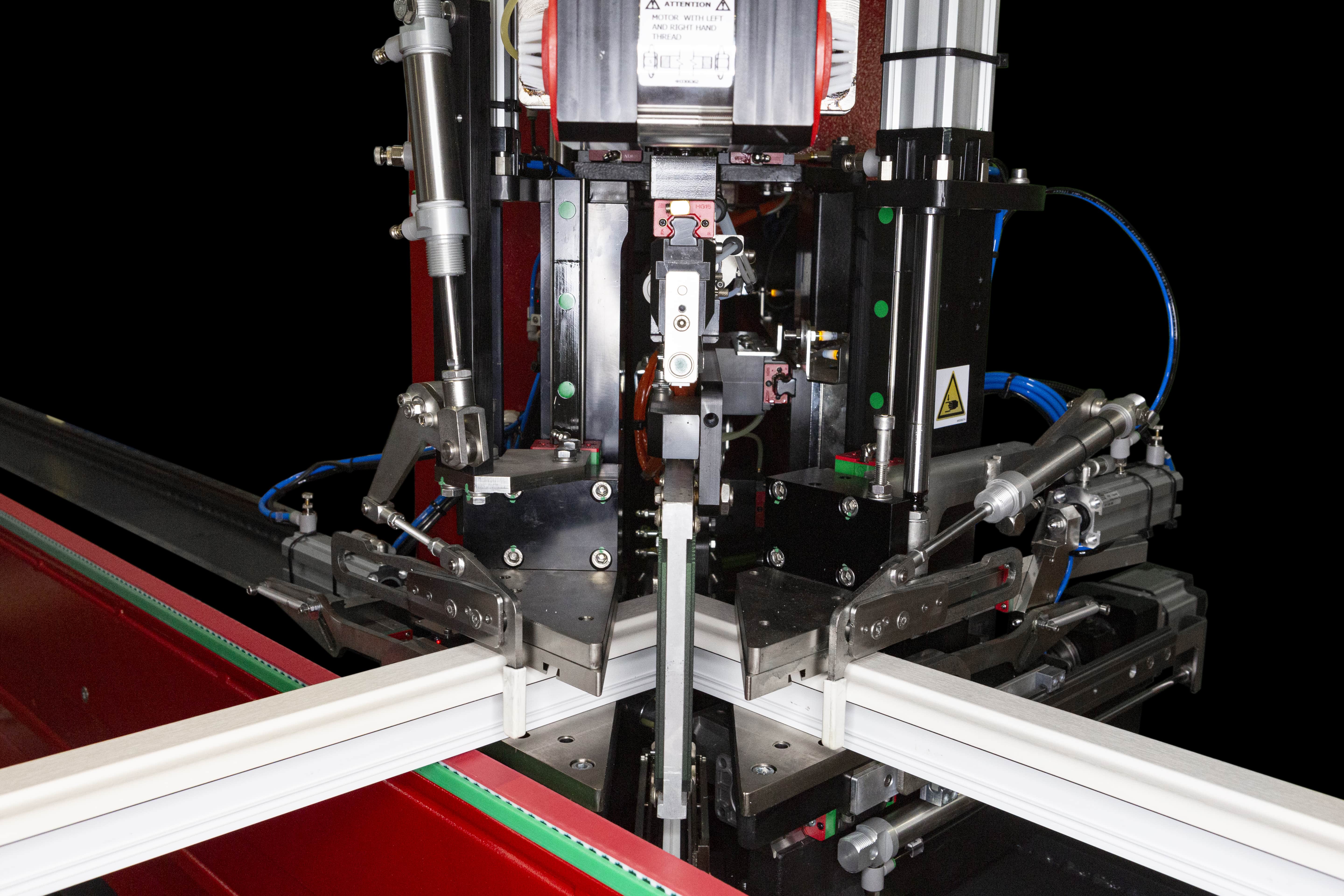

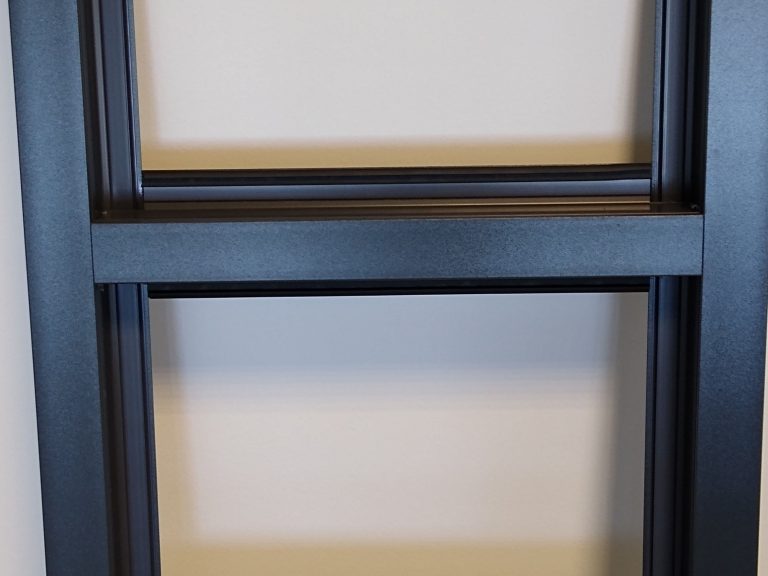

The first and only 6 CNC head welding machine in the world that completely eliminates the welding curb from the corner allowing you to obtain Pvc windows with uniform quality and superior aesthetics.

Natural evolution of the 4-head SL4-FF Evo, thanks to the 2 extra heads allows to weld simultaneously the 4 corners of a Pvc framework complete with 1 crosspiece (front welding) without the need for cleaning (Patented Seamless Welding) or subsequent retouching.

5 Reasons to choose the SL6 FF TR

Reduction of time and space: In a single cycle it welds simultaneously the 4 angles at 45° and 1 crosspiece in 90° mode.

Cost reduction: After welding, there is no need to clean or touch up and therefore neither the cleaner nor the turntable is needed.

Labor reduction: Not having to finish the corners, only 1 operator is required to load the profiles.

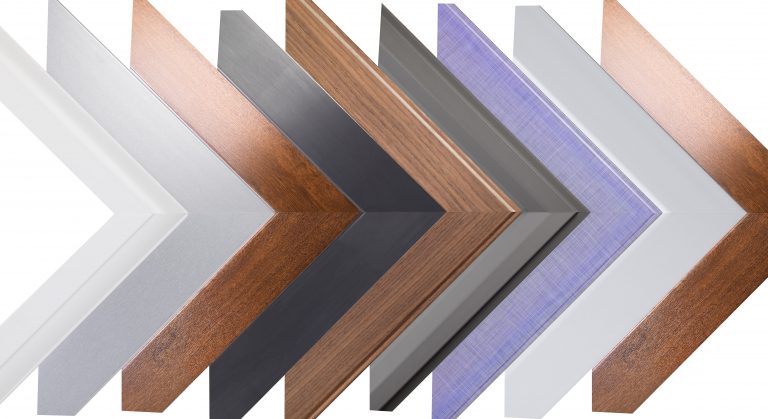

Possibility to weld profiles coated with any type of film or foil such as anodized aluminum, painted aluminum, painted Pvc and Pvc covered with natural wood or acrylic.

Solves the problem of profile tolerances: A special automatic calibration system allows to compensate it.

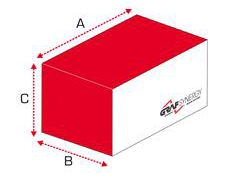

Dimensions

-

Length (A)

6.000 mm -

Width (B)

5.600 mm -

Height (C)

2.200 mm -

Weight

5.300 Kg

Details

-

Installed power

20 Kw -

Supply

400 V -

Air consumption per cycle

200 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Welded frames*

Up to 1/140 sec.

* Depends on type of profiles, seals, geometry and welding seam.

Weldable Dimensions

Sash/Frame

-

Height

58 ÷ 180 mm -

Width

40 ÷ 130 mm

Transom

-

Height

58 ÷ 100 mm -

Width

50 ÷ 130 mm

Profile

-

Maximum

3.200 x 4.000 mm (on request up to 6.000 mm) -

Minimum*

370 x 520 mm

* It changes depending on the profile used.

Upon request the machine can be equipped with:

- Increased cooling table for sizes 3628, 4028, 4528, 5028.

- Y axis increase 4.000 mm.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA