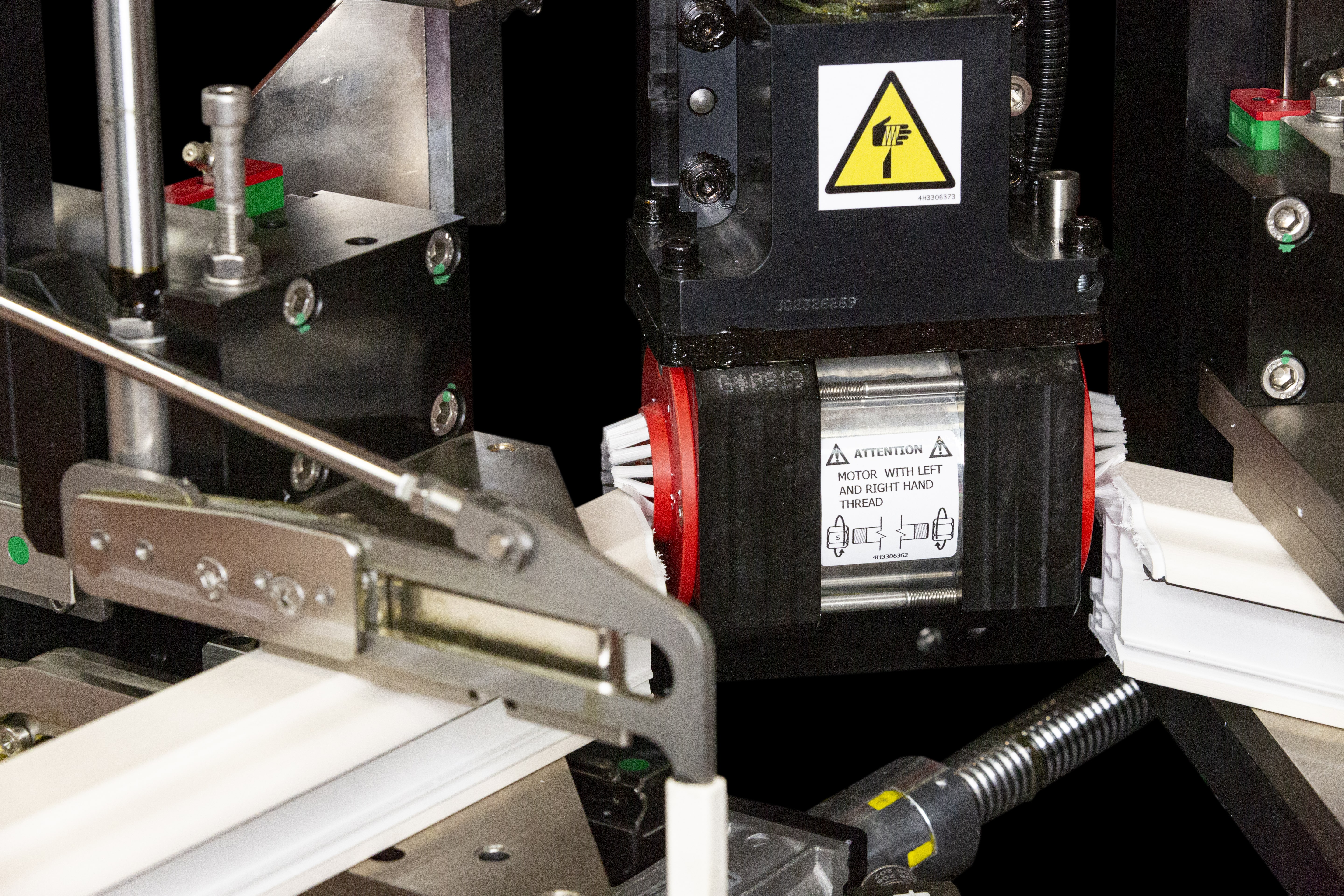

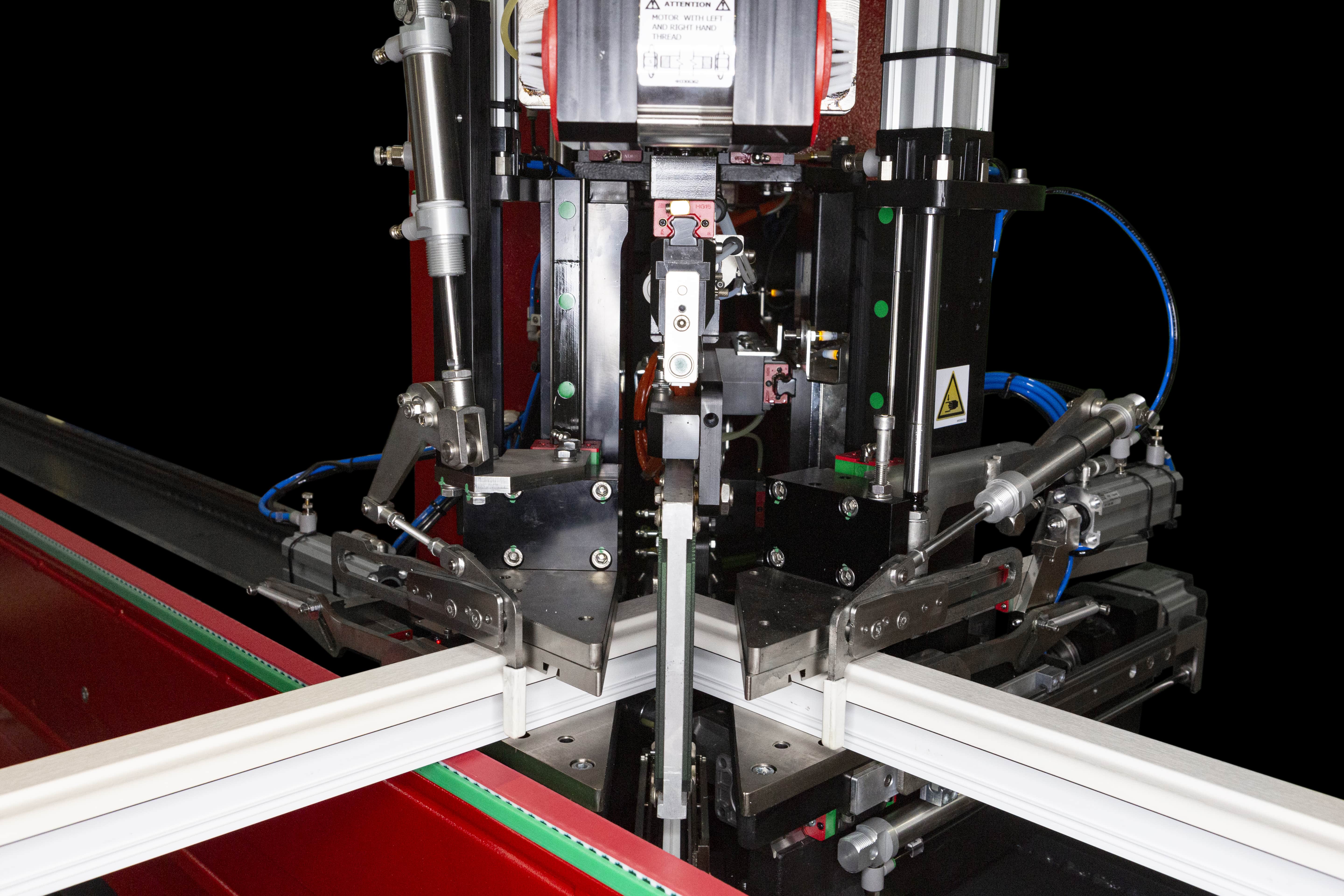

CNC 4-head Welding machine

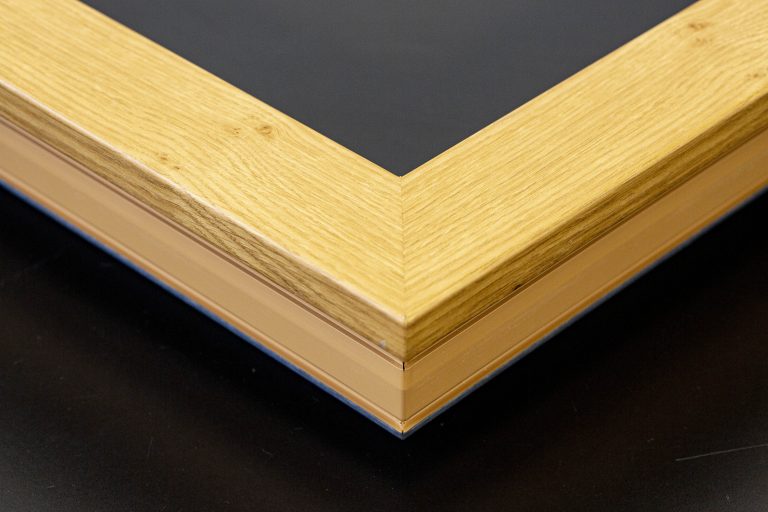

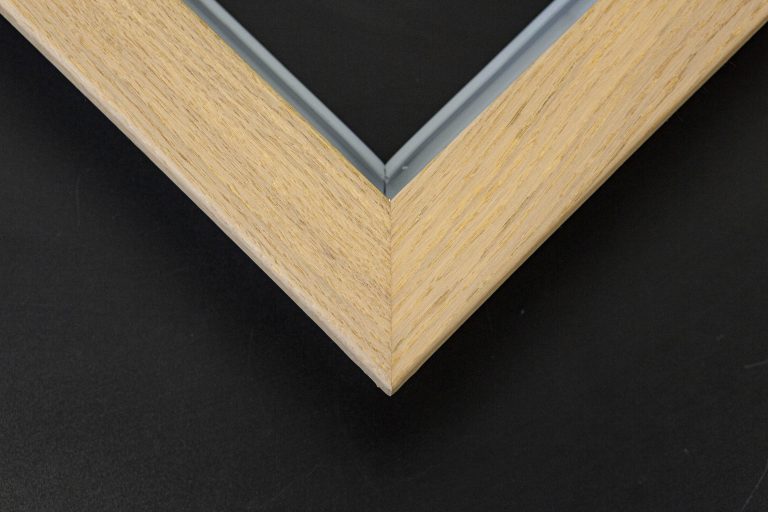

The first and only 4-head CNC welding machine in the world that completely eliminates the welding bead from the corner and allows you to weld profiles with a joint that simulates the assembly angle of a wooden window frame on one of the faces.

Unique machine of its kind, it performs both seamless welds with traditional angle joined at 45° and “Timber look” effect closures for which it welds one side at 45° and that of the opposite face at 90° while maintaining uniform quality and superior aesthetics.

5 Reasons to choose the SL4 FF WD

Flexibility: Plant that makes seamless welding and “Timber Effect”.

Possibility to weld profiles coated with any type of film or foil such as anodized aluminum, painted aluminum, painted Pvc, Pvc covered with natural wood or acrylic.

Time and cost reduction: After welding, it must not be cleaned or retouched, therefore the cleaner or the workpiece turning table are not required and only 1 operator is required.

Active Welding System: The operator can intervene in advance on the expected final result.

Solves the problem of profile tolerances: It has a special automatic calibration system that allows you to compensate for the profile tolerances.

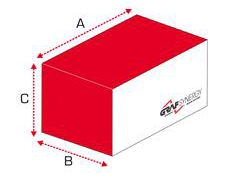

Dimensions

-

Length (A)

6.000 mm -

Width (B)

5.100 mm -

Height (C)

2.200 mm -

Weight*

da 3.000 Kg

Note: It change according to the configuration required.

Details

-

Installed power

17 Kw -

Supply

400 V -

Air consumption per cycle

180 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Welded frames*

Up to 1/90-150 sec.

* Dependent on the types of profiles and gaskets to be processed.

Weldable Profile Dimensions

-

Height

35 ÷ 180 mm -

Width

40 ÷ 130 mm

Weldable Side Dimensions

-

Maximum

3.200 mm (on request up ot 6.000 mm) -

Minimum

370 mm

Upon request the machine can be equipped with:

- Mobile unloading belts with lateral movement.

- Cooling table.

- C-Welding.

- 3-sided door framing welding U (including C-welding).

- Exhauster.

- Software for converting imported data files.

- Production data monitoring: Control of all the data of the welded elements deriving from the optimization and manual production over time (change time of the countershims, monitoring of the working time, monitoring of the time for unloading from the cooling table).

- Electronic control system of countershims.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA