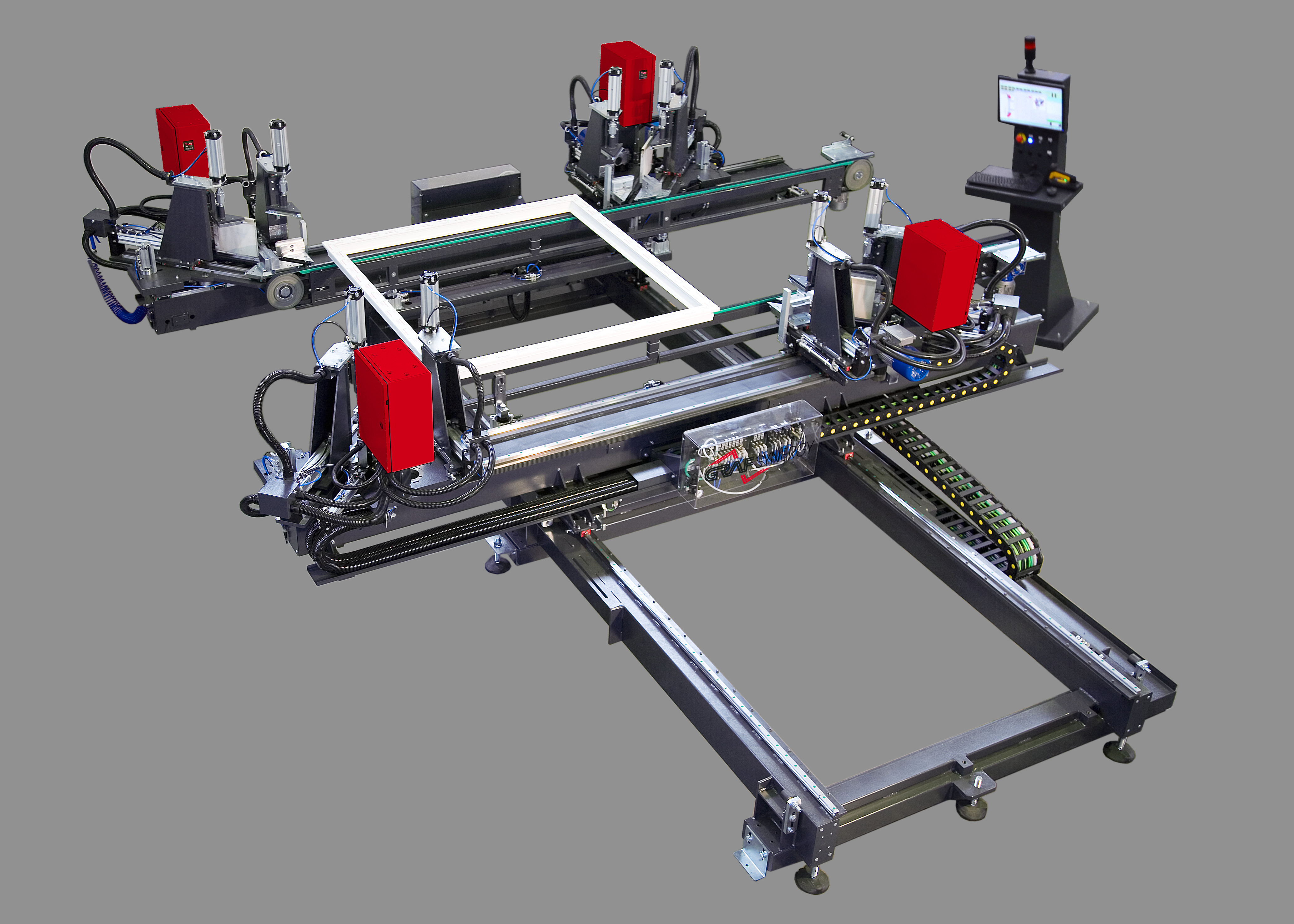

CNC 4-head welding machine

4-head CNC welding machine with 3 controlled axes, designed for horizontal and simultaneous welding of the 4 corners of a Pvc frame; ensures the frame manufacturer with constant operating quality over time.

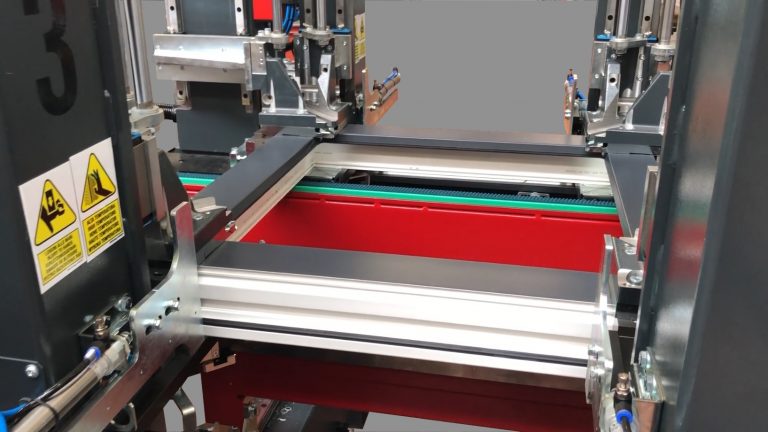

It automatically performs all the necessary operations, positioning at the welding positions, cyclical fusion, compression and cooling and, at the end of the process, it releases the frame on conveyor belts towards the cleaning area.

5 Reasons to choose the SL4-4

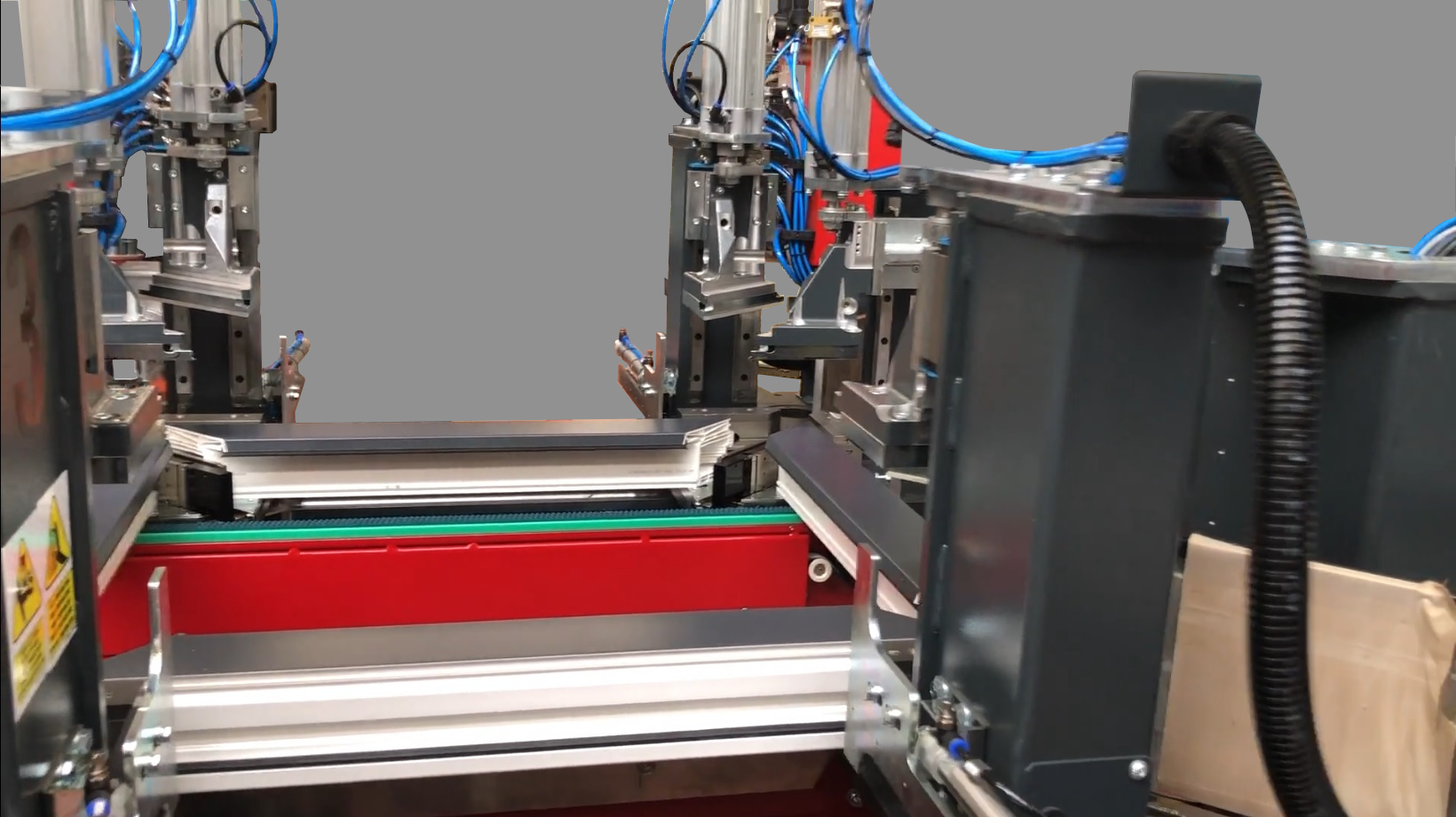

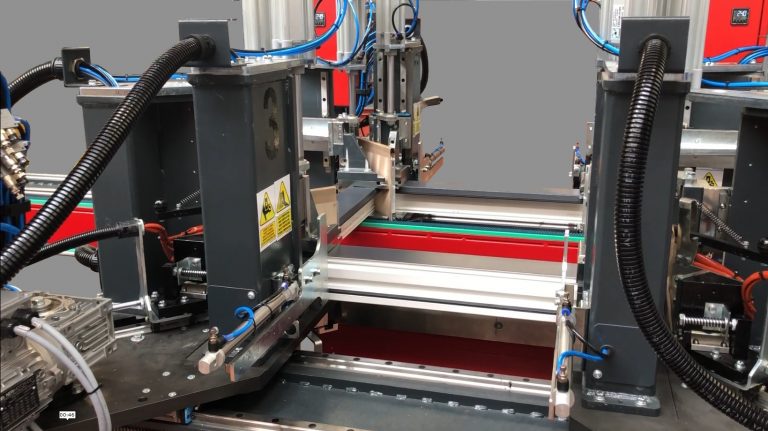

Superior quality welding: Absolutely flat and homogeneous surfaces.

Quick replacement system for welding countershims.

Quick change of the non-stick coating on the welding plates.

Automatic burn regulation (5÷6 mm).

User Friendly technology.

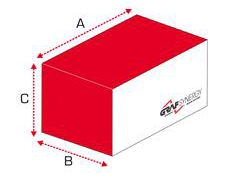

Dimensions

-

Length (A)

5.250 mm -

Width (B)

2.200 mm -

Height (C)

1.650 mm -

Weight

2.100 Kg

Details

-

Installed power

12 Kw -

Supply

400 V -

Air consumption per cycle

180 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Machined frames/8h*

Up to 240

* Dependent on the types of profiles and gaskets to be processed.

Weldable Profile Dimensions

-

Height

40 ÷ 130 mm -

Width

40 ÷ 130 mm

Weldable Frame Dimensions

-

Maximum

3.200 x 2.800 mm -

Minimum

400 x 400 mm

Upon request the machine can be equipped with:

- Cooling table.

- Possibility of connection in line with Graf Synergy corner cleaning machines.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA