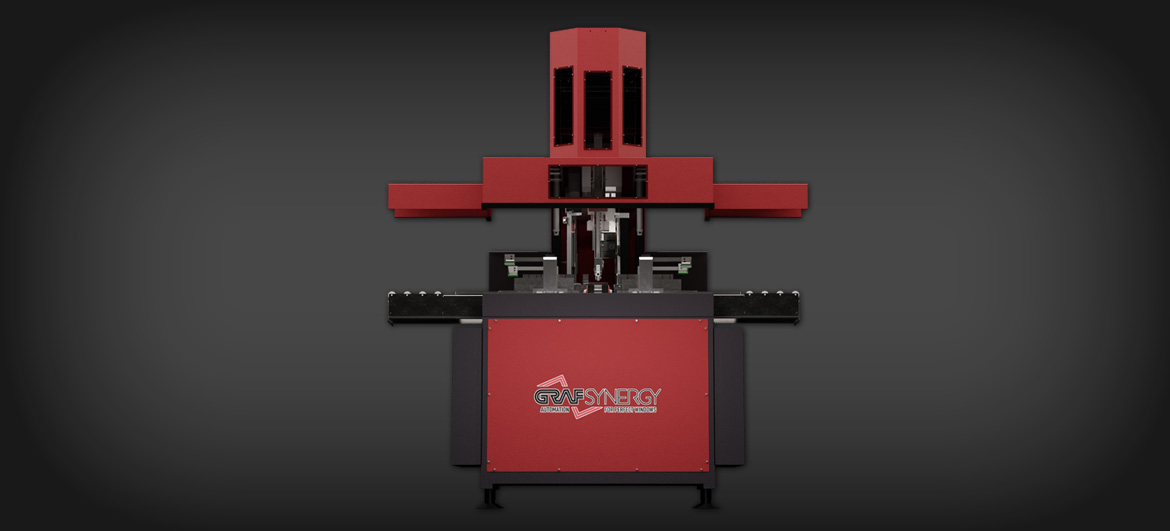

CNC 1-Head Welding machine

First and only machine one-head welding machine CNC conceived particularly for the welding between frames and transoms at 180° type reverse butt. It allow a double welding simultaneously (2+2).

The machine remove completely from the corner the welding corb allowing to obtain PVC windows with a uniform quality and superior aesthetics.

It make perfect welds ensuring surfaces absolutely flat and homogeneous even with profiles that, in place of metal reinforcement, have inside products not weldable like fiberglass, aluminum or resin.

5 Reasons to choose the SL FF RB

Possibility to weld profiles covered with any kind of film or foil as anodized Aluminium, painted Aluminium, the painted Pvc, the covered Pvc with natural wood or acrylic.

Reduction of time and costs: After the welding it’s not necessary to clean or retouch and therefore it’s not necessary the cleaning machine and the turn table pieces.

Labor reduction: Not having to retouch the corners 1 operator who charge the profiles it’s enough.

Size reduction: Machine extremely compact.

Solves the problem of profile tolerances: It has a special automatic calibration system that allows you to compensate the profiles tolerances.

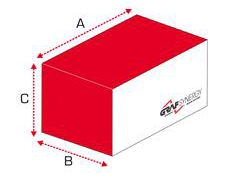

Dimensions

-

Length (A)

1.550 mm -

Width (B)

1.300 mm -

Height (C)

2.500 mm -

Weight

1.000 Kg

Details

-

Installed power

6 Kw -

Supply

400 V -

Air consumption per cycle

100 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Weldable Profile Dimensions

-

Height

40 ÷ 100 mm -

Width

60 ÷ 110 mm

Weldable Side Dimensions

-

Maximum

There are not limits caused by the machine -

Minimum

300 mm

Upon request the machine can be equipped with:

Exhauster

Machine version in compliance with UL/CSA

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA