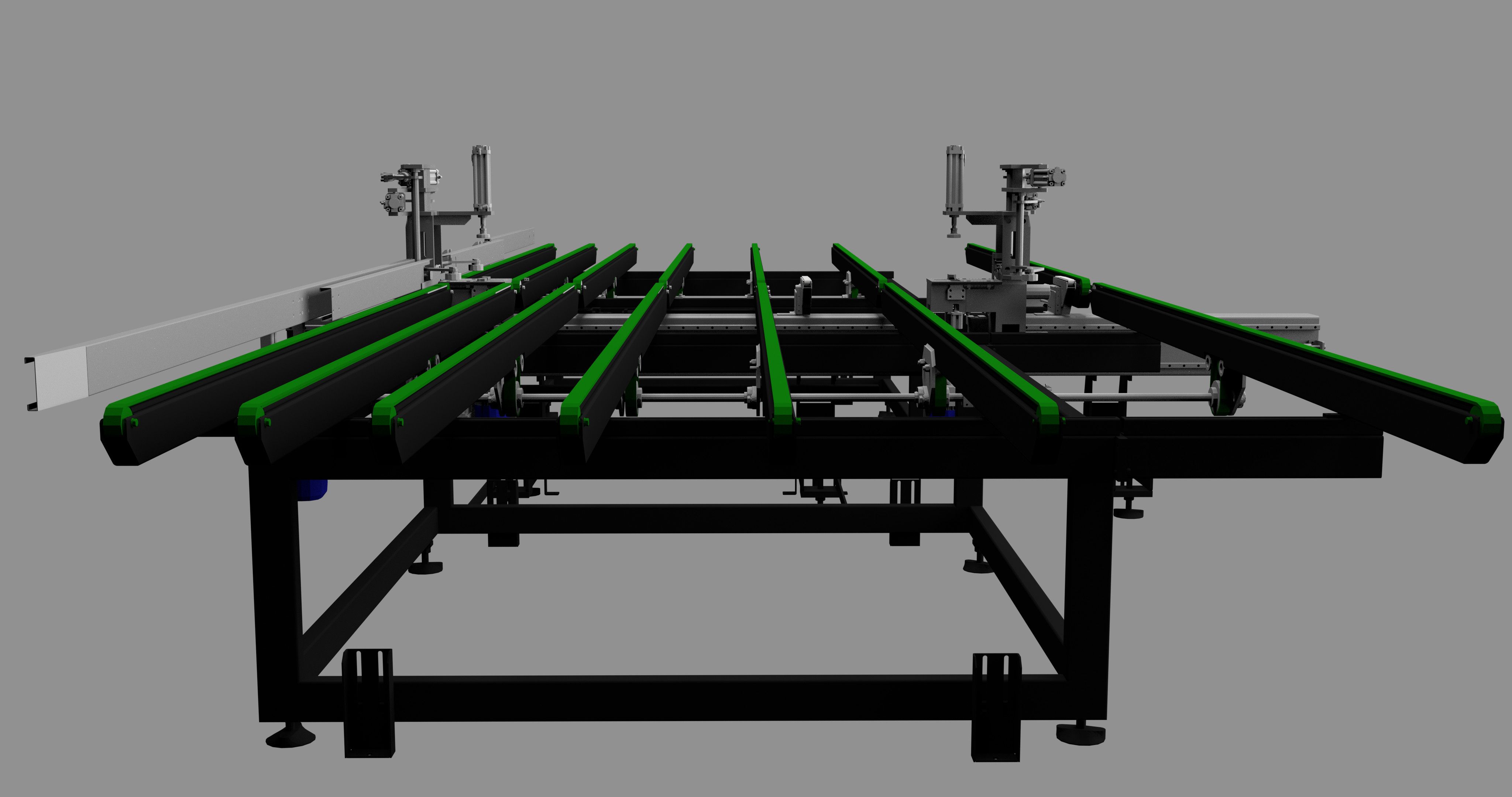

Table for the automatic execution of Hinge holes

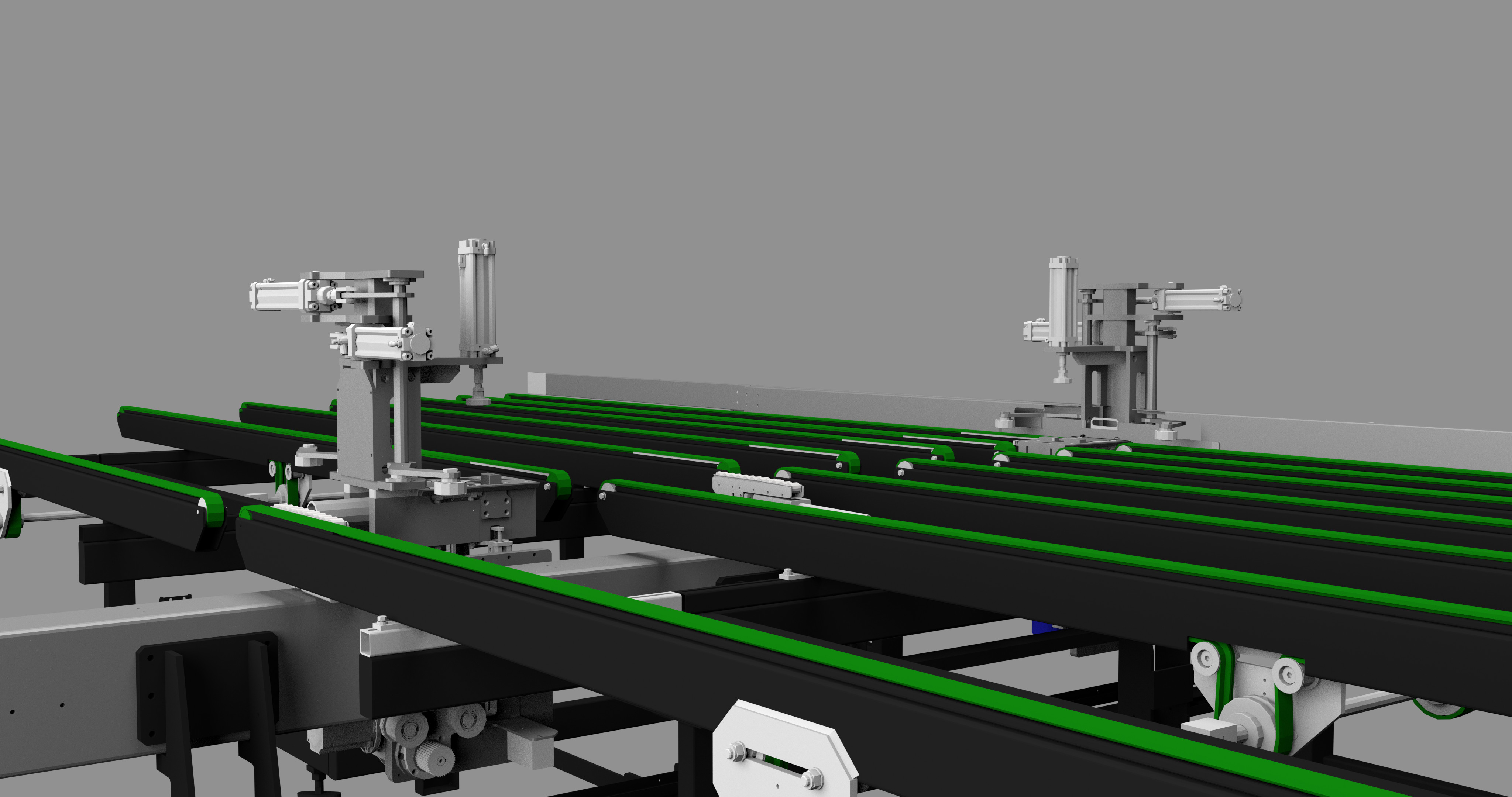

CNC drilling table with 3 controlled axes designed to automatically perform the hinge holes on the frames.

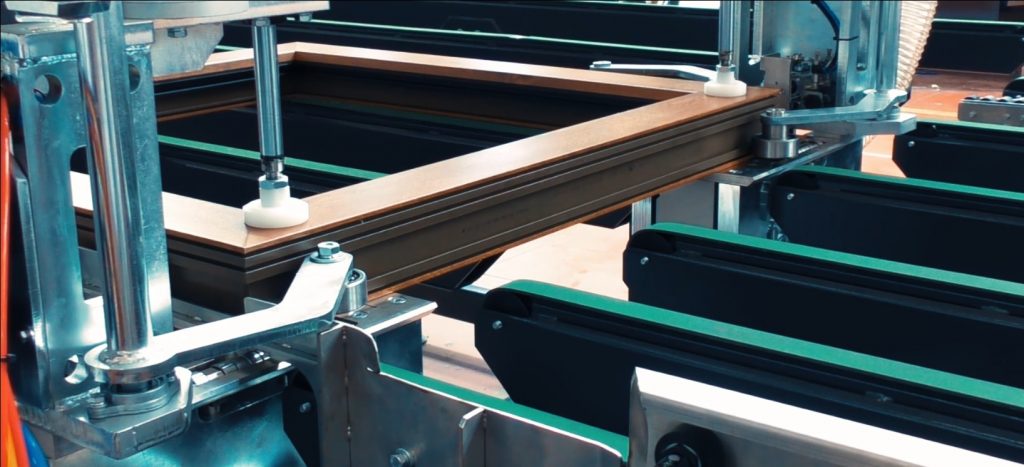

HDH ensures a perfect PVC drilling cycle, managed by an automatic drilling depth regulator and is equipped with an automatic reset sequence at the end of the processing.

5 Reasons to choose HDH

Lower labor costs: Automatically moves the squares and the necessary holes.

Greater Precision: Measurements made automatically based on the internal width of the glazing bead on the panel already welded.

Optimisation of spaces: Replacing the cooling table of the welder allows production lines with reduced dimensions.

Chip braker system: It favors the elimination of waste by preventing it from getting stuck, ruining the profiles and avoiding the machine stops necessary for cleaning.

User Friendly panel control: Simple and immediate management and easy configuration of the drilling parameters.

Dimensions

-

Length (A)

8.000 mm -

Width (B)

4.500 mm -

Height (C)

1.800 mm -

Weight

1.500 Kg

Details

-

Installed power

5 Kw -

Supply

400 V -

Air consumption per cycle

10 Nl/min -

Minimum Operating Pressure

8 bar -

Operators

1

Performance

-

Frames produced/8h*

Up to 240

* Dependent on profile type and production line.

Workable Frame Dimensions

-

Based on the productivity of the welding machine

3.200 x 2.800 mm -

4.000 x 2.800 mm

On request the machine can be equipped with:

- There are no optional elements.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA