Hardware Mounting Table

Table designed and built to carry out the assembly and screwing of the hardware on the PVC window frames in an automated manner.

Prepared for insertion into an automated production line, it consists of 2 stations: The preparation table that shows the elements to be assembled and the compartment in which they are located, and the automatic screwing table where thanks to a portal with 2 screwdrivers, the hardware is fixed on all 4 sides of the sash.

5 reasons to choose Faz III

Non-stop production : While the hardware components are screwed on, the next frame can already be pre-assembled.

Possibility of in line insertion thanks to automated transport systems.

Simple and intuitive graphical interface: it help the inexperienced operator in choosing the hardware.

High execution speed: Over 50% faster than a semi automatic system.

Optimization of work spaces and correct storage of the hardware inside the production island.

The system is able to automatically manage 2 different types of screws, selecting the corresponding one based on the type of hardware and is equipped with an automatic screwing depth regulator.

Once the hardware has been cut and positioned, the pre-assembled panel is automatically transported to the second station and the operator can simultaneously begin the pre-assembly of the next sash.

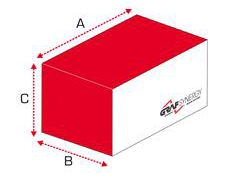

Dimensions

-

Lenght (A)

7.300 mm -

Width (B)

3.200 mm -

Height (C)

2.510 mm -

Weight

1.800 Kg

Details

-

Installed Power

8 Kw -

Power Supply

400 V -

Air Consumption

200 Nl/min -

Operating Pressure

7 bar

Preparation Table

Structure

Table for inserting hardware elements.

Machining

Hardware positioning and cutting.

Screwing Table

Structure

Portal with 2 High Speed screwdrivers with Automatic screwing depth regulator and Automatic screw selection

Machining

Screwing.

Performance

Up to 480 Frames/8h.

* Depends on the type of profile and hardware used.

Operators

1

Sash Dimensions Machinable Automatically

-

Maximum

2.500 x 1.200 mm -

Minimum

350 x 500 mm

Door Profile Width Machinable

-

Maximum

130 mm -

Minimum

50 mm

Upon request the machine can be equipped with:

- Hardware programming according to the types of windows

- Variant for the use of screws with special sizes.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA