Hardware Mounting Table

Bench designed and built to carry out the assembly and screwing of the hardware on the PVC window frames in an automated manner.

The unit consists of 2 stations: the preparation table and the screwing table: in the first the panel is pre-assembled (cutting and positioning of the hardware) which is then automatically transported to the second where 2 pneumatic screwers fix the hardware; the operator can simultaneously begin the pre-assembly of the next sash.

5 Reasons to choose FAZ II

Non stop production: While the hardware components are screwed on, the next square can already be pre-assembled.

Possibility of connection in line of production thanks to automated boxing systems.

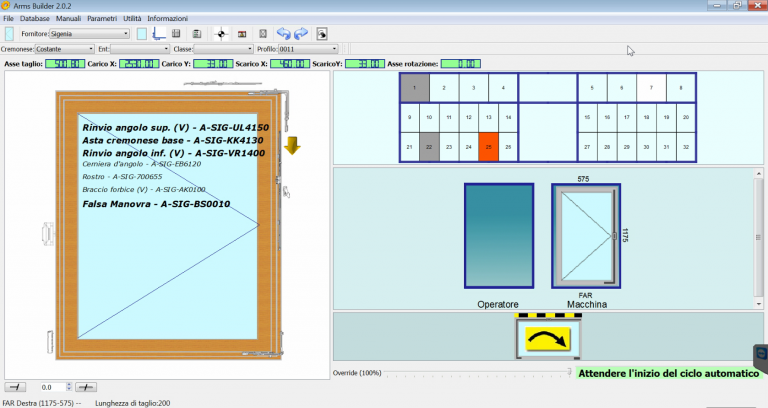

Simple and intuitive graphic interface that which also guides the inexperienced operator in choosing the hardware.

Software with wide database for program management of types of windows.

Workspace optimization and correct storage of the hardware inside the production island.

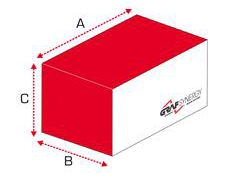

Dimensions

-

Length (A)

6.750 mm -

Width (B)

3.760 mm -

Height (C)

2.500 mm -

Weight

1.800 Kg

Details

-

Installed power

4.5 Kw -

Supply

400 V -

Air consumption per cycle

800 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Frames produced/8h*

Up to 240

* Depends on the type of profile and hardware used.

Automatically workable frame dimensions

-

Maximum

2.500 x 1.200 mm -

Minimum

350 x 500 mm

Automatically machinable profile width

-

Maximum

130 mm -

Minimum

50 mm

Preparation Table

Structure

Machinings

- Cutting and positioning hardware.

Note: The software indicates on the monitor the compartment in which the element to be picked up is stored in the 32-compartment storage warehouse. A light signal then facilitates its finding.

Screwing Table

Structure

2 High Speed screwdrivers with automatic screwing depth regulator and automatic screw selection.

Automatic 180° rotation device.

Machinings

- Screwing.

Upon request the machine can be equipped with:

- Variant for the use of screws with special sizes.

- Automatic unloading table.

- Recliners shuttle.

- Hardware programming according to the types of windows.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA