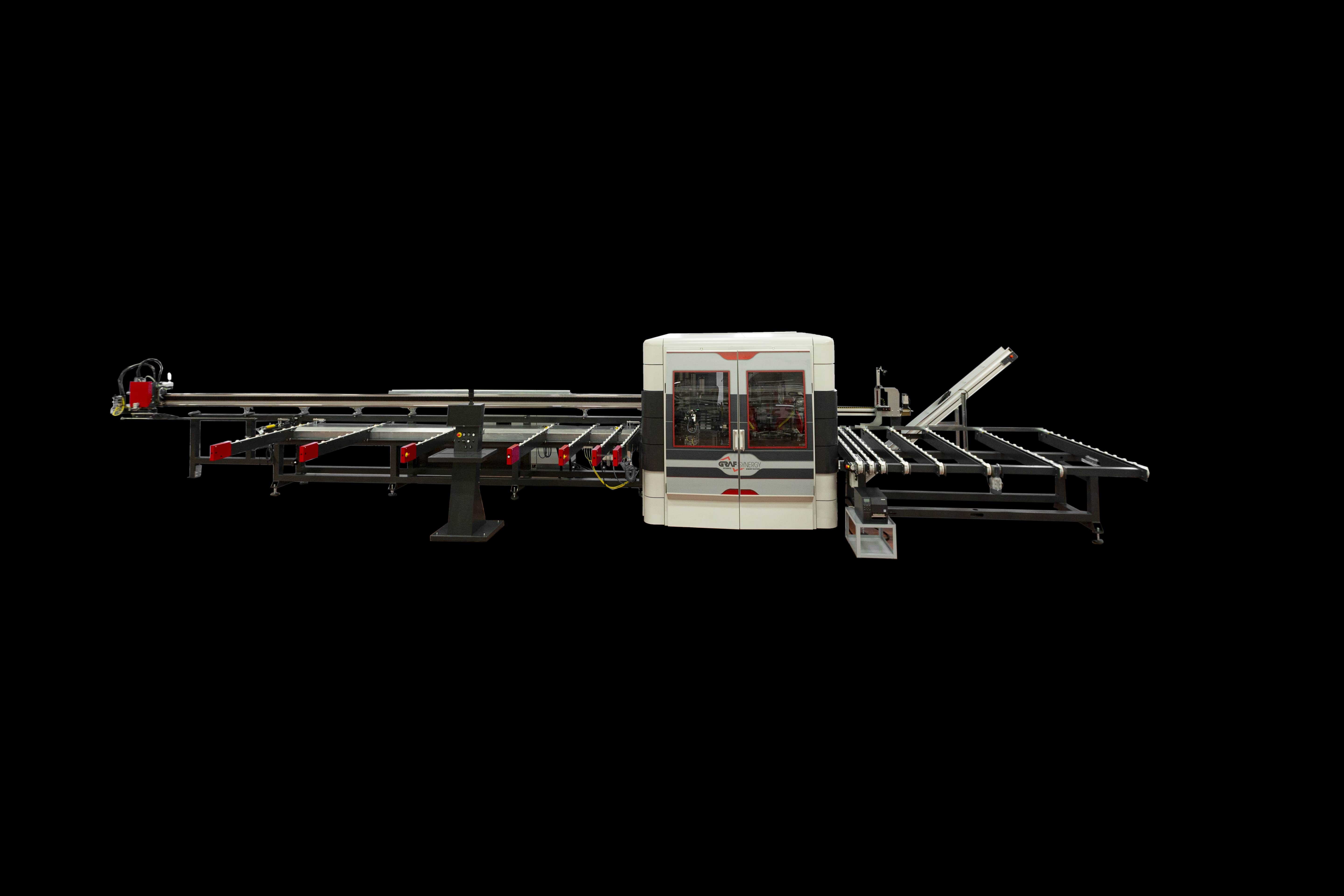

3-blade Cutting Center

CNC controlled 6-axis cutting center dedicated to window and door frames requiring high levels of productivity (up to 500 one-sash windows/8h*).

Maximum expression of mechanical and technological innovation, it allows cutting of extremely high precision and speed, while maintaining reliability and efficiency unchanged over time.

* Dependent on the type of profiles to be cut, types of 1-sash windows and installed options.

5 Reasons to choose Cut 3B

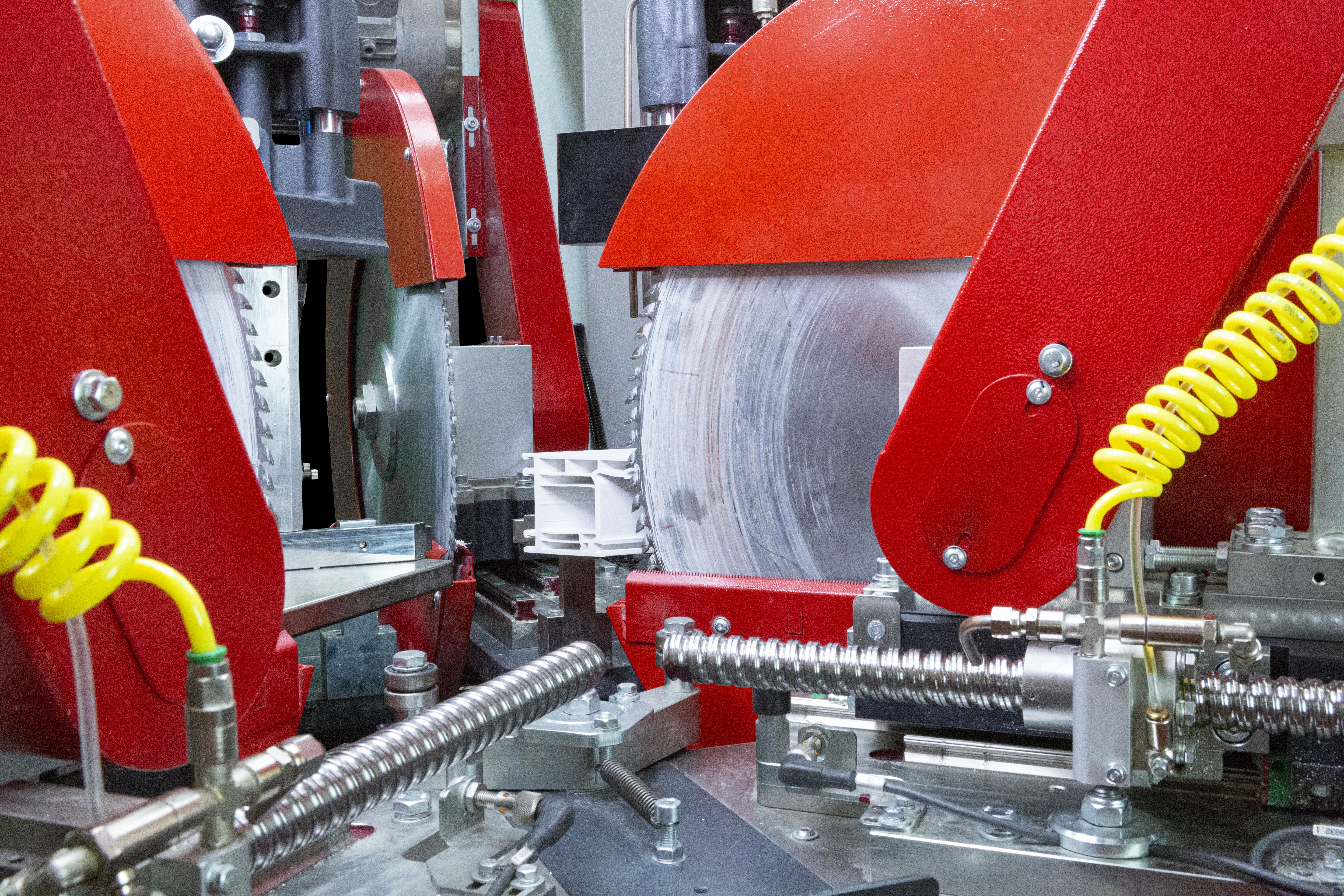

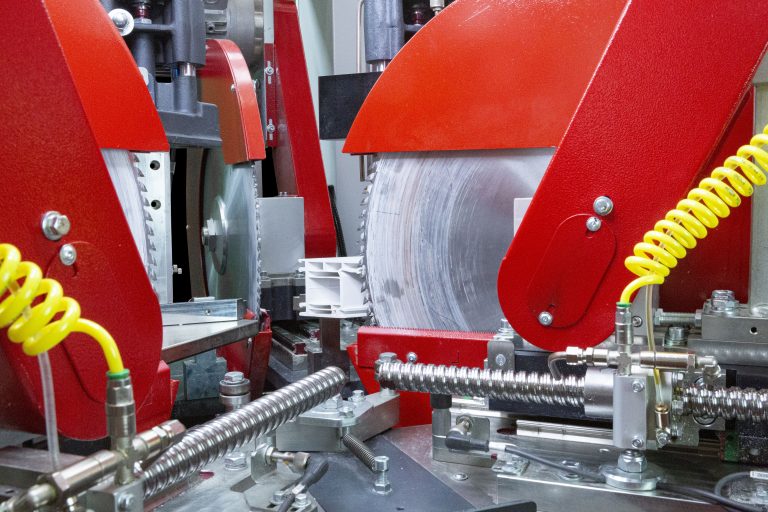

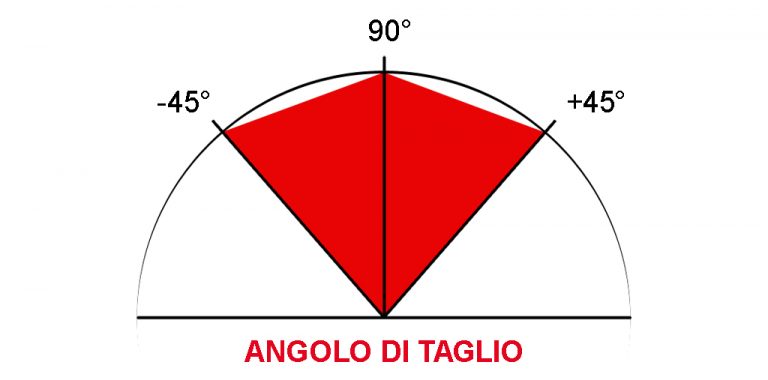

Very High Execution Speed: 3-blade cutting module with synchronized horizontal movement.

Very High Adaptability to profiles with sections of particular sizes.

Optimize Production lists: Fewer bars used thanks to Graf Synergy software.

Maximum precision: Automatic profile alignment system (it linearizes the bar that is not perfectly straight) and CNC profile gripper with reading of the real position by means of a centesimal magnetic strip.

User Friendly Technology: Intuitive system for simple management of work cycles.

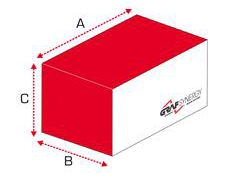

Dimensions

-

Length (A)

13.250 mm -

Width (B)

3.400 mm -

Height (C)

2.800 mm -

Weight

3.000 Kg

Details

-

Installed power

14 Kw -

Supply

400 V -

Air consumption per cycle

120 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

One-sash produced/8h*

Up to 500

* Dependent on the type of profiles to be cut, types of 1-sash windows and installed options.

Automatically loadable profile dimensions

-

Length

700* / 6.500 mm -

Width

40 / 130 mm -

Height

40 / 180 mm

* 400 On request.

Loading Module

- Loading magazine with max. capacity of 8 bars

- Automatic bar loading system with straps

- Bar gripping system using a 2-axis CNC gripper controlled by a prismatic guide linear motor with position reading on a centesimal magnetic strip

Unloading Module

- Automatic unloading of cut profiles

- Straps unloading table with safety photocell

- Max. Capacity of unloading 15/20 pieces

On request the machine can be equipped with:

- STATS: Software for the analysis of production data that reports the timing of daily, weekly, monthly and annual operations.

- Fly Optimizer: Automatic measurement system of the bar remains that allows you to optimize the production list again in order to reuse the production leftovers.

- Retrieve option: The application allows you to re-insert the pieces to be machined again in the cutting lists following production errors, a new cutting list optimized for these.

- Customized solution for adapting the machine to profiles with particular shapes (post technical analysis).

- Chippings conveyor - Version 1.200 mm or 2.000 mm.

- Exhauster with 2 bags.

- Customized soundproof booth.

- Motorized unloading table with belts with output on the opposite side of the loading.

- Possibility of predisposition for automatic connection to 1 or 2 ASG-E screwing centers.

- Manual labeling machine.

- Labeling machine with automatic label applicator.

- Single or double laser for marking the profiles.

Available Variants

Preparation for cutting aluminum profiles.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA