Cutting and Working automatic Center

CNC controlled axis cutting and machining center designed to perform the machining and cutting of profiles in an optimized way on Pvc profiles.

Compact and versatile, it is a plant built with the most innovative technology available on the market and, working 2 or 4 bars simultaneously, guarantees a very high productivity.

Extremely customizable machine, it is composed in its basic version of a bar loading station where a multiple gripper system driven by a brushless motor and a cutting module with 2 blades ascending are supplied which guarantee extremely precise cuts.

5 Reasons to choose CC 500

Versatile and customizable machine, extremely reliable over time.

Maximum precision over time: CNC Profile Gripper with reading of the real position through a centesimal magnetic strip.

User Friendly Technology: Intuitive and simple menu-driven software.

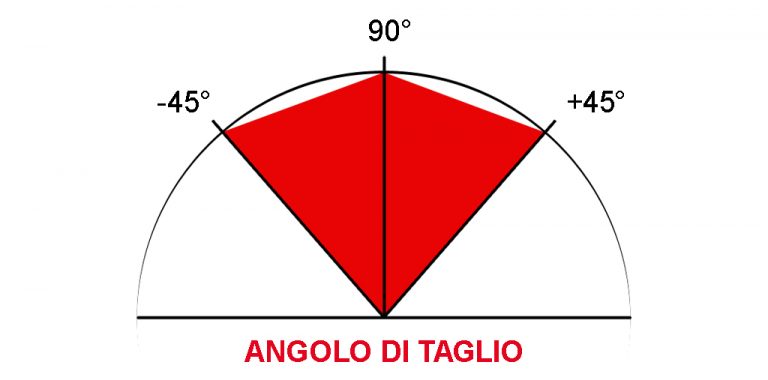

High Technology: Extremely flexible work unit capable of accommodating pneumatic, electric and punching spindles in variable numbers; Main blade set for 45° or 90° cuts and secondary blades for composite cuts (Notch).

Production list management: It allows to automatically import and execute cutting and work lists.

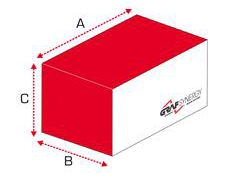

Dimensions

-

Length (A)

14.000 mm -

Width (B)

2.200 mm -

Height (C)

2.200 mm -

Weight

3.000 Kg

Details

-

Installed power

12 Kw -

Supply

400 V -

Air consumption per cycle

180 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Bars worked/8h

Depending on the chosen configuration

Automatically loadable profile dimensions

-

Length

700 / 6.500 mm -

Width

40 / 130 mm -

Height

40 / 130 mm

Loading Module

- Bar pre-loading station (max capacity 10/12 bars).

- Multiple CNC gripper system with real position reading via centesimal magnetic stripe.

Unloading Module

- Automatic extractor of the cut profiles on a unloading table

- Unloading warehouse with safety photocell

- Max. Capacity of unloading 15/20 pieces

On request the machine can be equipped with:

- Configuration with Electric spindle.

- Configuration with Pneumatic spindle.

- Configuration with Punching-spindle.

- Bar gripping system with 1-axis CNC gripper controlled on a linear motor on a prismatic guide.

- STATS: Software for the analysis of production data that reports the timing of daily, weekly, monthly and annual operations.

- Fly Optimizer: Automatic measurement system of the bar remnants which allows to optimize again the production list in order to reuse the production leftovers.

- Customized solution for adapting the machine to profiles with particular shapes (post technical analysis).

- Conveyor - Version 1.200 mm or 2.000 mm.

- Vacuum cleaner with 2 bags.

- Manual labeling machine.

- Unloading table extension.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA