Machining Center and Reinforcement Screwing

Unique machine of its kind, it works on Pvc profiles with the metal reinforcement already inserted.

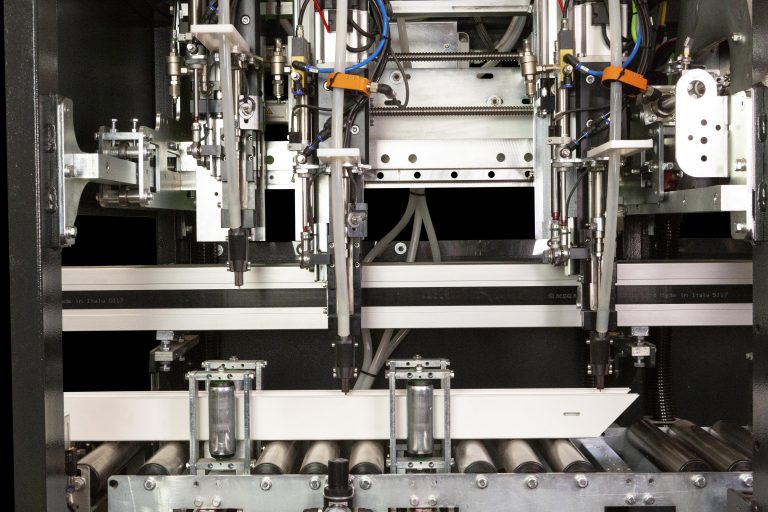

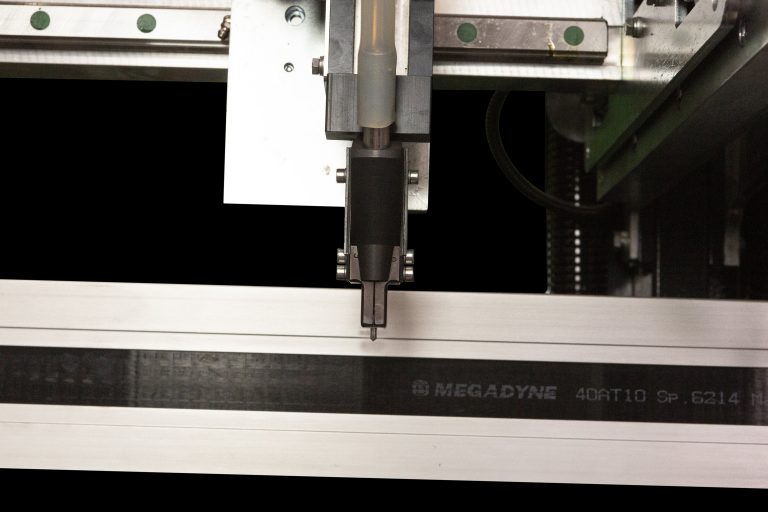

It is a CNC system that, thanks to a fixing module that can accommodate up to 3 screwdrivers (1 standard) and various tools with independent movement, allows you to carry out the various processes - screwing the reinforcement, holes for fixing to the wall, crosswise holes and triple handle hole - in an extremely precise and accurate way.

5 Reasons to choose ASG-E

Extremely precise machining: Working on Pvc profiles with the metal reinforcement already inserted.

Control of each screwing parameter (position, screw depth, torque and screwing speed).

Possibility to install the system both in a stand alone version and in line with any Graf Synergy cutting and machining center.

Modern Brushless Screwdrivers: Speed, accuracy, quietness and low energy consumption.

Chipbreaker System: By favoring the elimination of waste, it prevents it from getting stuck, ruining the profiles thus avoiding the machine stops necessary for cleaning.

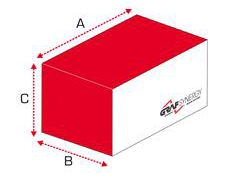

Dimensions

-

Length (A)

2.400 mm -

Width (B)

9.300 mm -

Height (C)

2.000 mm -

Weight

1.450 Kg

Details

-

Installed power

5 Kw -

Supply

400 V -

Air consumption per cycle

800 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Frames produced/8h*

Up to 200

* Dependent on processes and type of profile used.

Automatically loadable profile dimensions

-

Length

300 / 3.500 mm -

Width

40 / 130 mm -

Height

40 / 130 mm

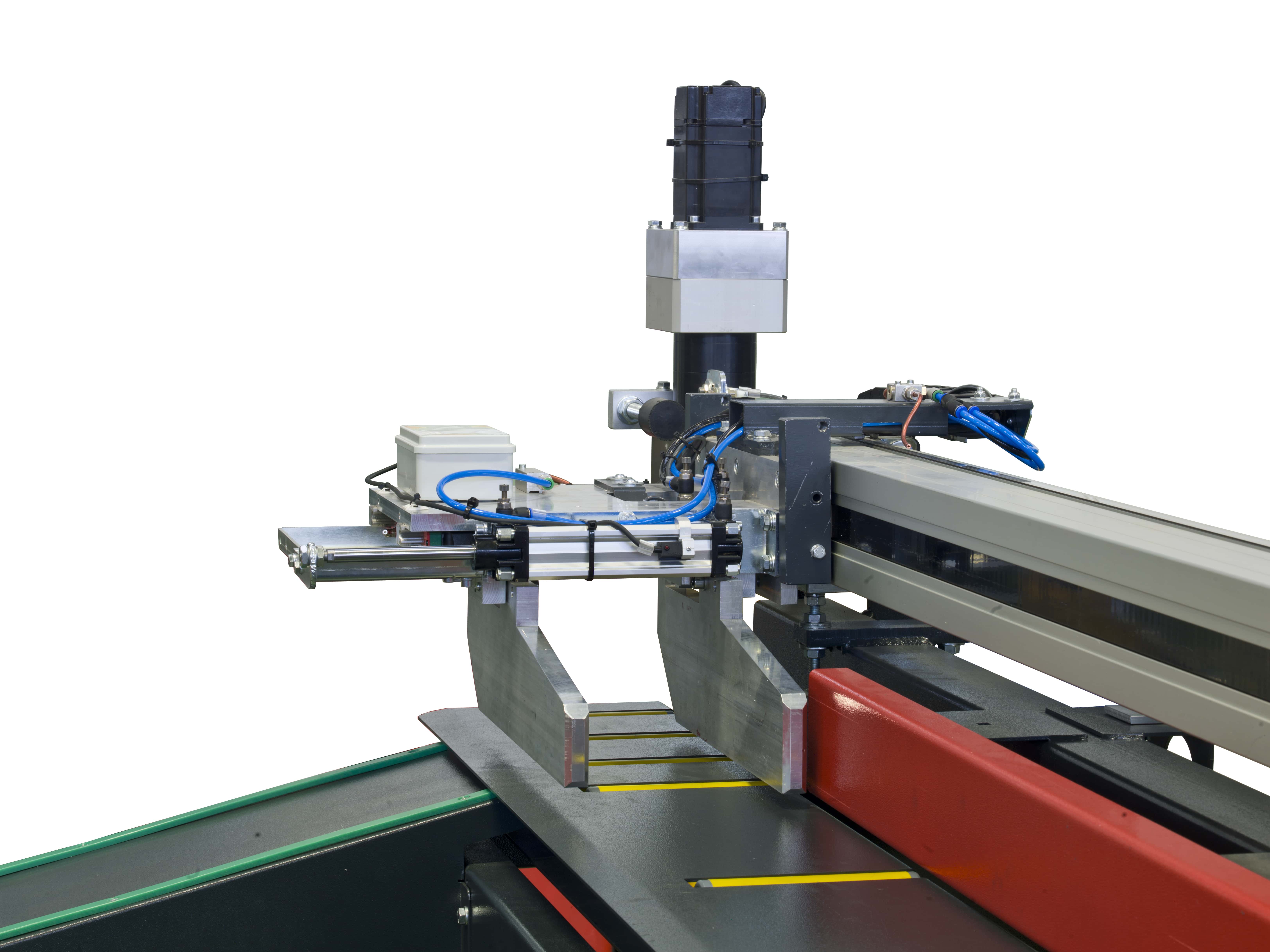

Loading Module

- Loading magazine with max. Capacity of 10 bars

- Piece loading system with straps

- Profile gripper moved by brushless motor and prismatic guides with position reading on centesimal magnetic strip

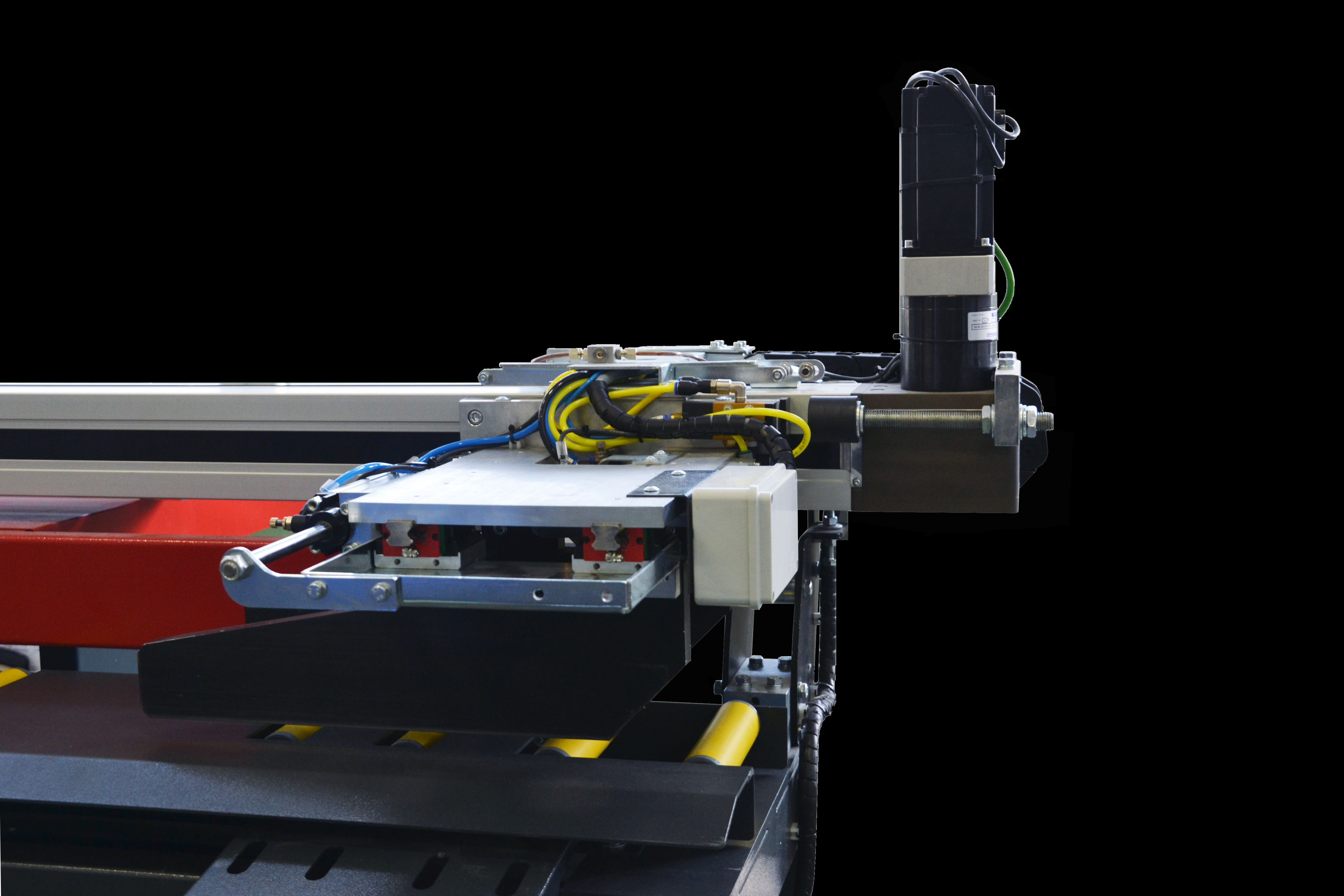

Unloading Module

- Automatic extractor for cut profiles

- Full unloading magazine with safety photocell

- Max. unloading capacity 10/12 pieces

Screwing Module

Structure

1 vertical screwdriver operated by brushless motor.

Transversal positioning of the screwdriver on the y axis.

Machinings

- Screwing of reinforcements

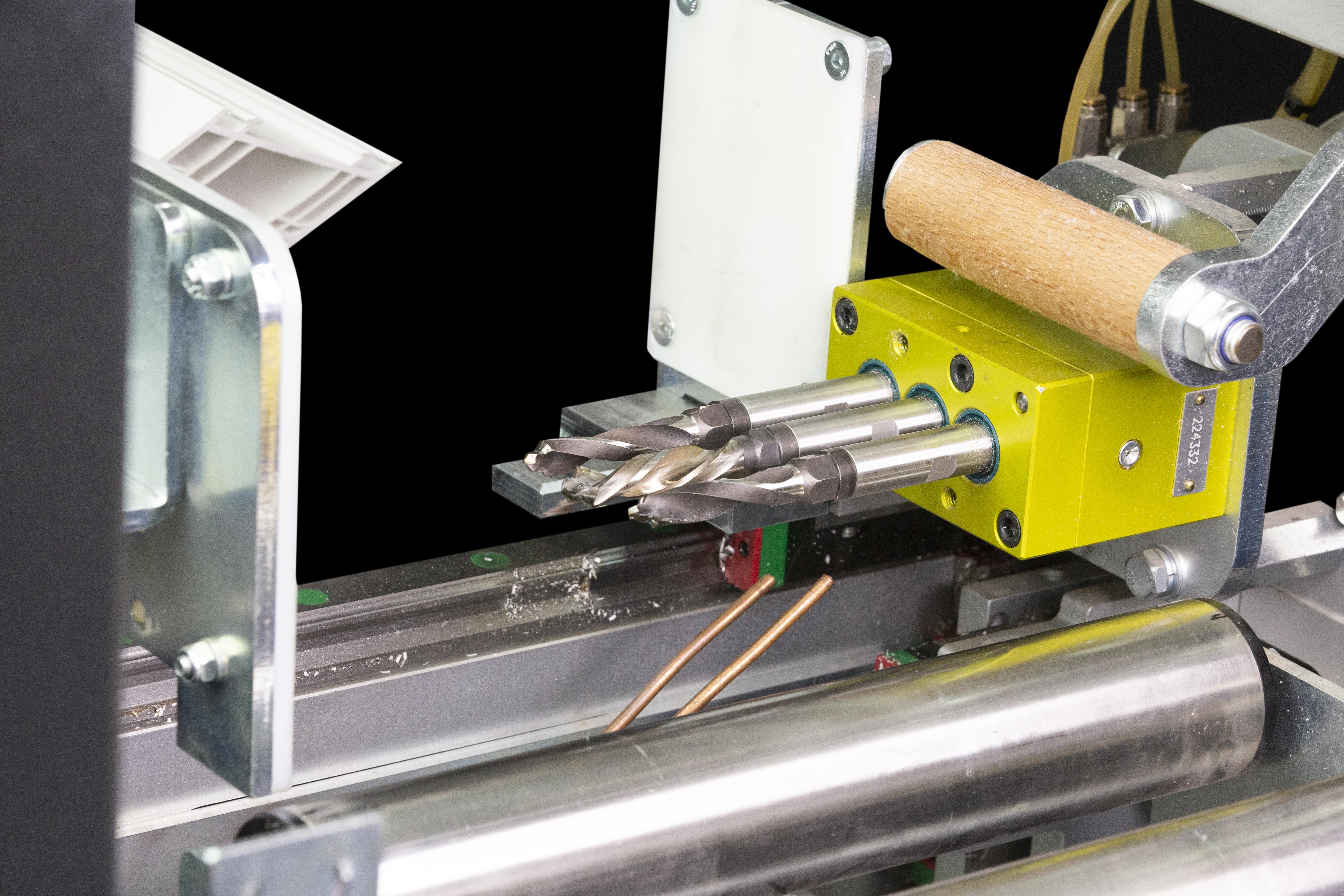

Machining Module

Structure

High Speed spindles.

Independent movement in y and x axes.

Machinings

- Holes for wall fixing

- Crosswise holes

- Triple handle hole

Upon request the machine can be equipped with:

- Max Dimensions Profile length automatically loaded extensible up to 6.000 mm.

- Max Dimensions Profile height automatically loadable extensible up to 180 mm (after verification).

- Motorized unloading table with belts and safety photocell (possibility of exit on the opposite side to the load).

- Up to 2 optional screwdrivers with change of distance from the first automatically adjustable.

- Single drill to make wall fixing holes and cross hole.

- Pair of vertical tools with misaligned and independent movement to make the inclined wall fixing holes.

- Specific tool to make the Triple handle hole with Chipbreaker System and 2 vertical positions through revolver.

- Tool to make hinge holes.

- Control PC with Barcode Reader.

- Possibility of online connection through automatic tables.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA