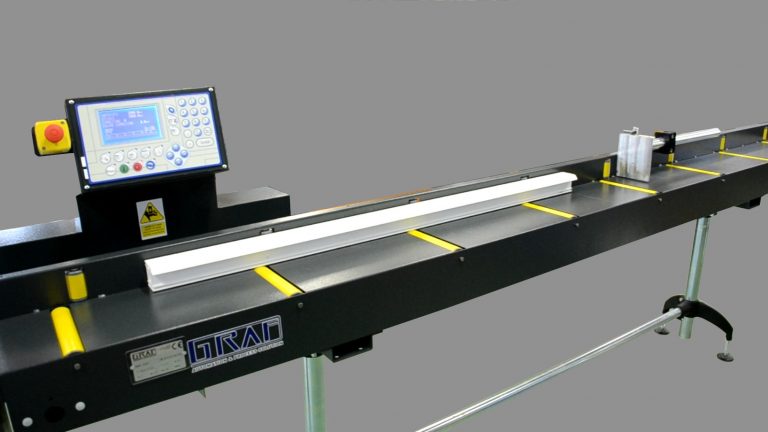

Roller conveyor with electronic positioning

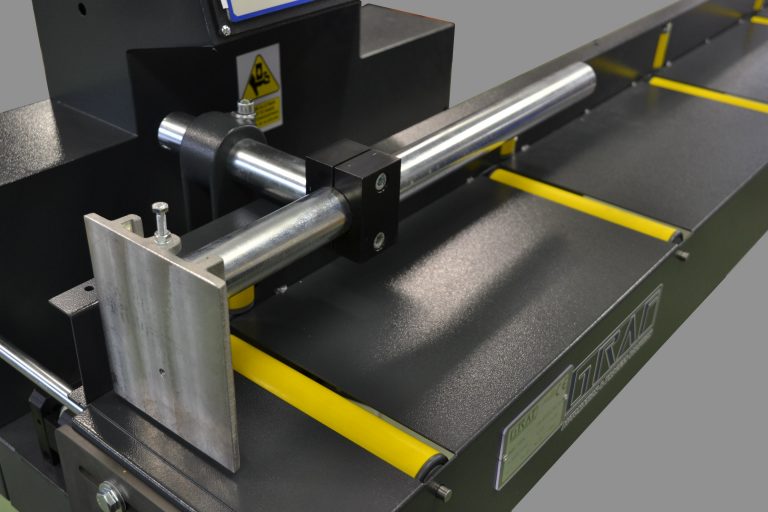

Unloading side roller conveyor equipped with a mobile stop driven by an electric motor with electronic positioning that determines the length of the profile to be cut.

Display of dimensions, images and messages via a 6-inch high brightness graphic display.

The positioning of the mobile stop can take place in the following ways:

- Directly by entering a measurement on the numeric keyboard.

- Through cutting lists received from management via Usb memory or directly from the network (Network card required).

- By receiving radio frequency from the appropriate caliber (Kit MSK 25/G233 required).

- By reading the barcode of the window (Requires barcode reader).

Equipped with both horizontal and vertical Vinyl rollers that facilitate the sliding of the cut pieces, is particularly suitable for the support and the reference in length of the pieces to be cut by a manual mitre saw (stoppers or profiles).

The support is available in 4 sizes according to the maximum size of the length of the bars to be machined, it has a load capacity per linear meter of 18 kg and its use is possible on both sides.

Dimensions

Model 3

-

Length (A)

3.600 mm -

Width (B)

800 mm -

Height (C)

1.400 mm -

Weight

140 Kg

Model 4

-

Length (A)

4.600 mm -

Width (B)

800 mm -

Height (C)

1.400 mm -

Weight

150 Kg

Model 5

-

Length (A)

5.600 mm -

Width (B)

800 mm -

Height (C)

1.400 mm -

Weight

160 Kg

Model 6

-

Length (A)

6.600 mm -

Width (B)

800 mm -

Height (C)

1.400 mm -

Weight

170 Kg

Details

-

Installed power

0.5 kW -

Supply

230 V - Monophase -

Operators

1

Technical characteristics of the control electronics

- 99 programmable profiles with alphanumeric code

- Automatic removal of the stop after each cut for easy removal of the cut piece

- Possibility to create own cutting lists to be recalled in memory for repetitive cycles.

- Storage of all the odds received by the Gauge in Radio Frequency.

- For each programmed profile it is possible to insert the following corrections:

1 Absolute correction.

4 Independent corrections according to the length to be cut (combined with the caliber, these vary according to the button pressed if the glazing bead is vertical or horizontal).

Note: Corrections according to length can be used with absolute value or as a percentage of the length to be cut. The operating mode is selectable by parameter. It follows therefore that the programmed corrections can be up to 495 which are calculated automatically on the position of the striker plate as a function of the length to be cut and the code of the glazing bead used.

On request the machine can be equipped with:

- Possibility of connection to a manual saw (electrical connection not included) for the automatic management of cutting lists received from the office.

- Kit MSK 25 / G233: Caliber for radio frequency data transmission and Receiver for roller conveyor with RS232 port.

- Bar code reader Radio CCD.

- 10/100 Mb network card for reading cutting lists from the network.

Italiano

Italiano  English

English  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português