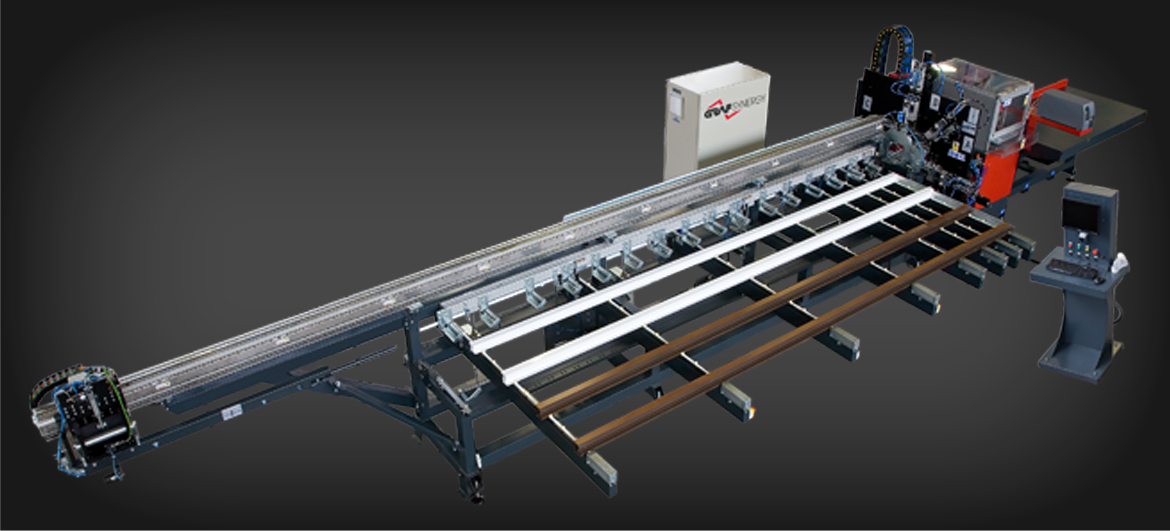

Automatic Cutting Center

CNC cutting center with 3 controlled axes, designed to perform cuts on Pvc profiles quickly and optimally.

Built with the most innovative technology is designed to perform all the required operations - profile loading from the bar magazine, cutting and unloading of the finished piece - in complete autonomy, without operator intervention.

5 Reasons to choose Linear Cut 500

Versatile, reliable and precise over time.

Optimizes production lists: Fewer bars used thanks to Graf Synergy software.

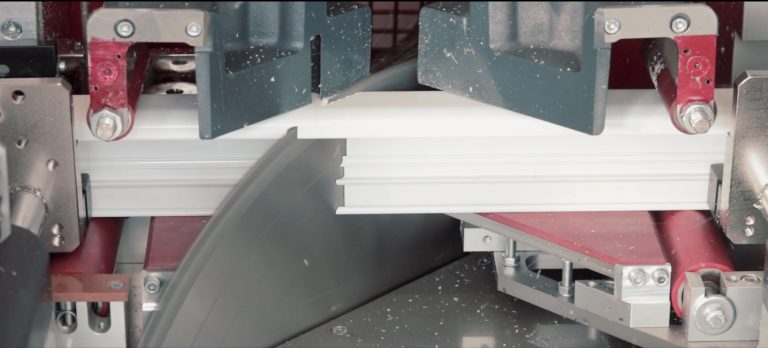

Maximum precision over time: Automatic profile alignment system (that linearizes the bar that is not perfectly straight) and CNC profile gripper with reading of the real position through a centesimal magnetic strip.

User Friendly Technology: Intuitive system for simple management of work cycles.

High Buy Back value.

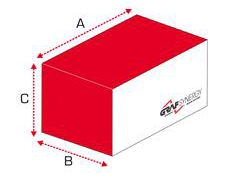

Dimensions

-

Length (A)

12.500 mm -

Width (B)

2.200 mm -

Height (C)

2.000 mm -

Weight

3.000 Kg

Details

-

Installed power

7 Kw -

Supply

400 V -

Air consumption per cycle

100 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

One-sash windows produced/8h*

Up to 300

* Dependent on processes and type of profile used.

Automatically loadable profile dimensions

-

Length

500 / 6.500 mm -

Width

40 / 130 mm -

Height

40 / 135 mm

Loading Module

- Loading magazine with max. capacity of 9 bars

- Bar loading system with straps

- 2-axis CNC profile gripper controlled by linear motor on prismatic guides

Unloading Module

- Automatic extractor of cut profiles on unloading table

- Unloading magazine with safety photocell

- Max. Capacity of unloading 15/20 pieces

On request the machine can be equipped with:

- Profile loading system for profile length from 400 to 700 mm.

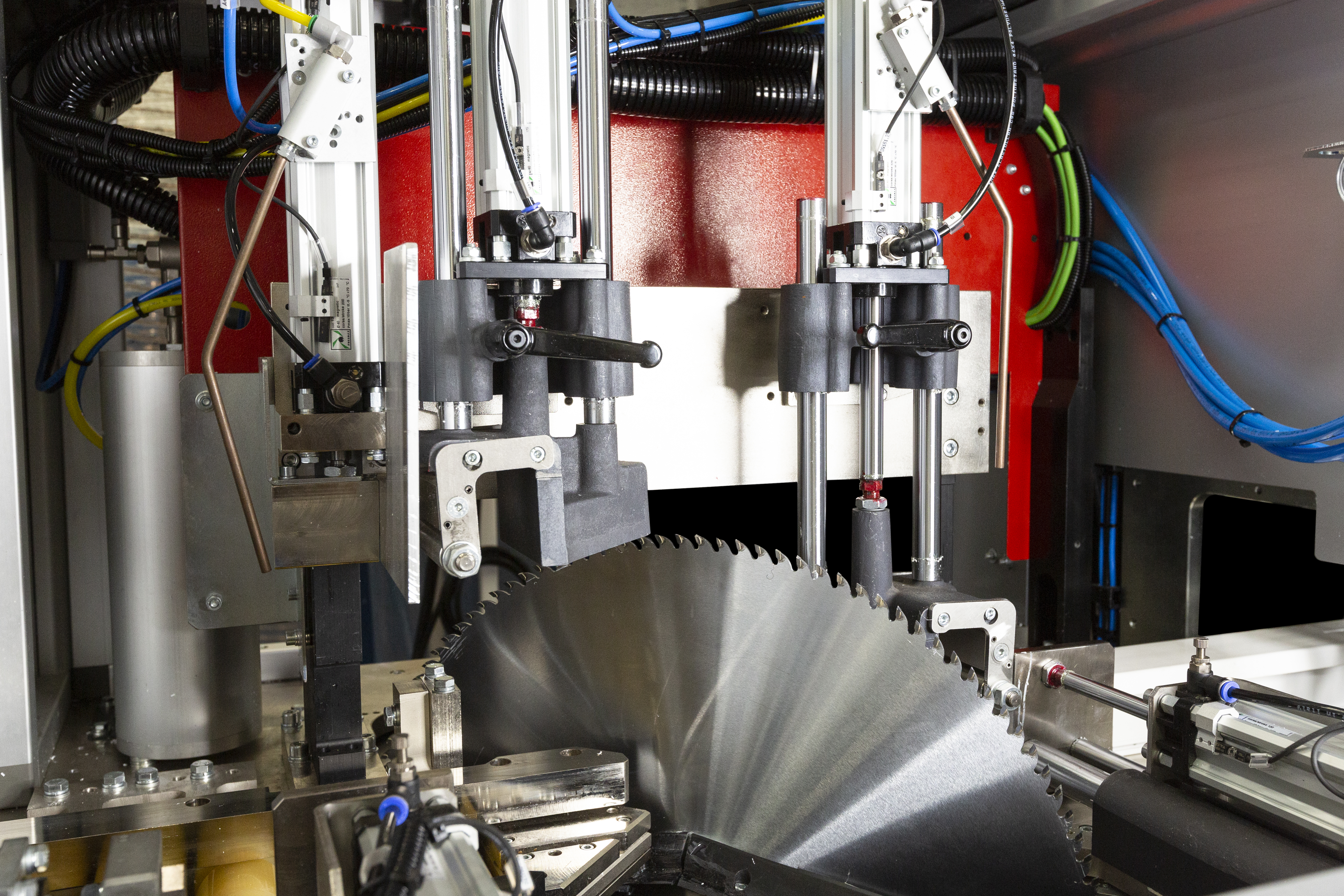

- Blade Ø 550 mm (necessary to cut 180 mm profiles) with additional presser kit.

- Possibility of inserting mechanical stops for fixed size intermediate cuts.

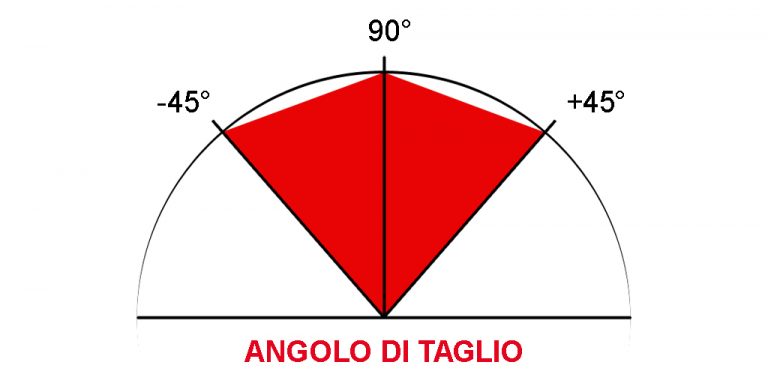

- Blade rotation by brushless motor for cuts at intermediate angles (between -45° and +45°).

- Fly Optimizer: Automatic measurement system of rest bar that allows you to optimize the production list again in order to reuse the production leftovers.

- Customized solution for adapting the machine to profiles with particular shapes (post technical analysis).

- Chip conveyor - Version 1.200 mm or 2.000 mm.

- Exhauster with 2 bags.

- Possibility of predisposition for automatic connection to 1 or 2 ASG-E screwing centers.

- Manual labeling machine.

- Horizontal profile clamps system with locking capacity for large section cuts (up to 230 mm).

- Unloading table extension.

- Profile width measurement sensor: Warns in case of wrong profile loading.

- Profile height measurement sensor: Warns in case of wrong profile loading.

- Horizontal clamps for cutting profiles 30-130 mm wide.

Available variants

Preparation for cutting aluminum profiles.

Possibility of integrating the V-Notch cutting unit.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA