CNC Cutting and Working center for Reinforcement

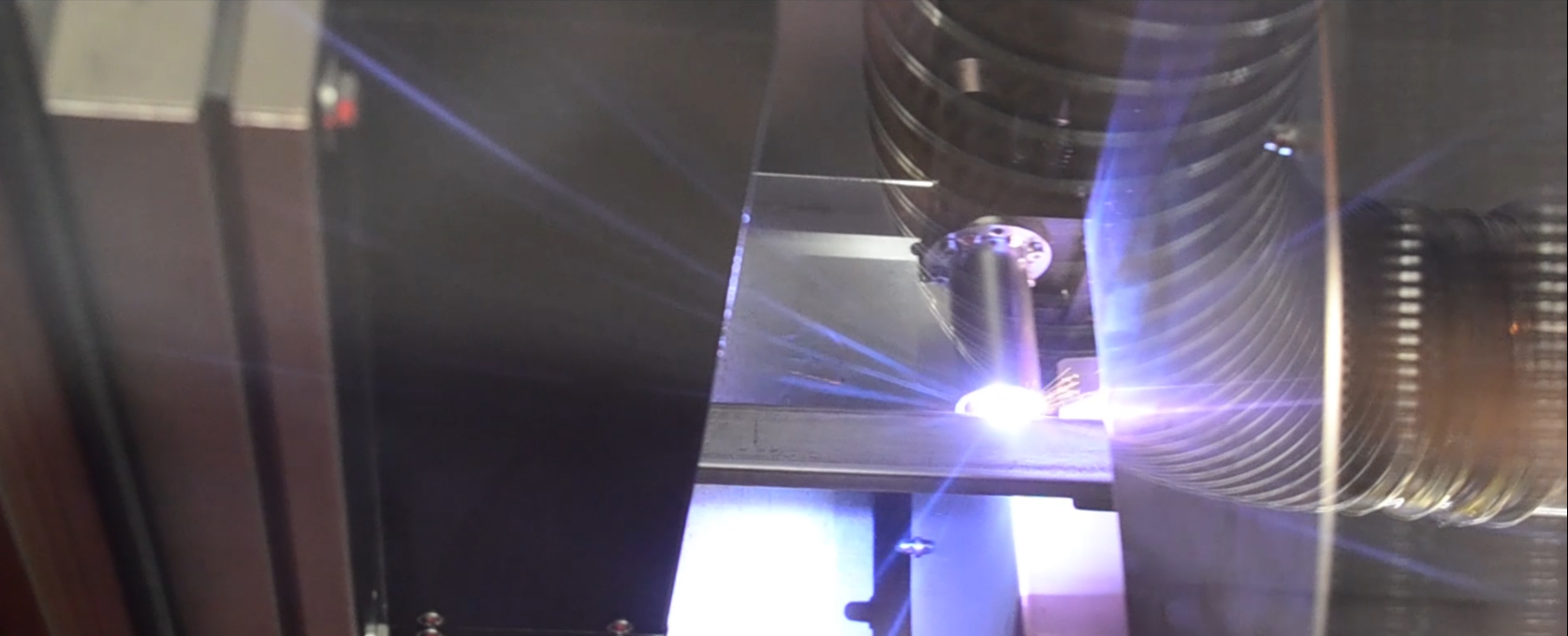

Plasma + Cut combined

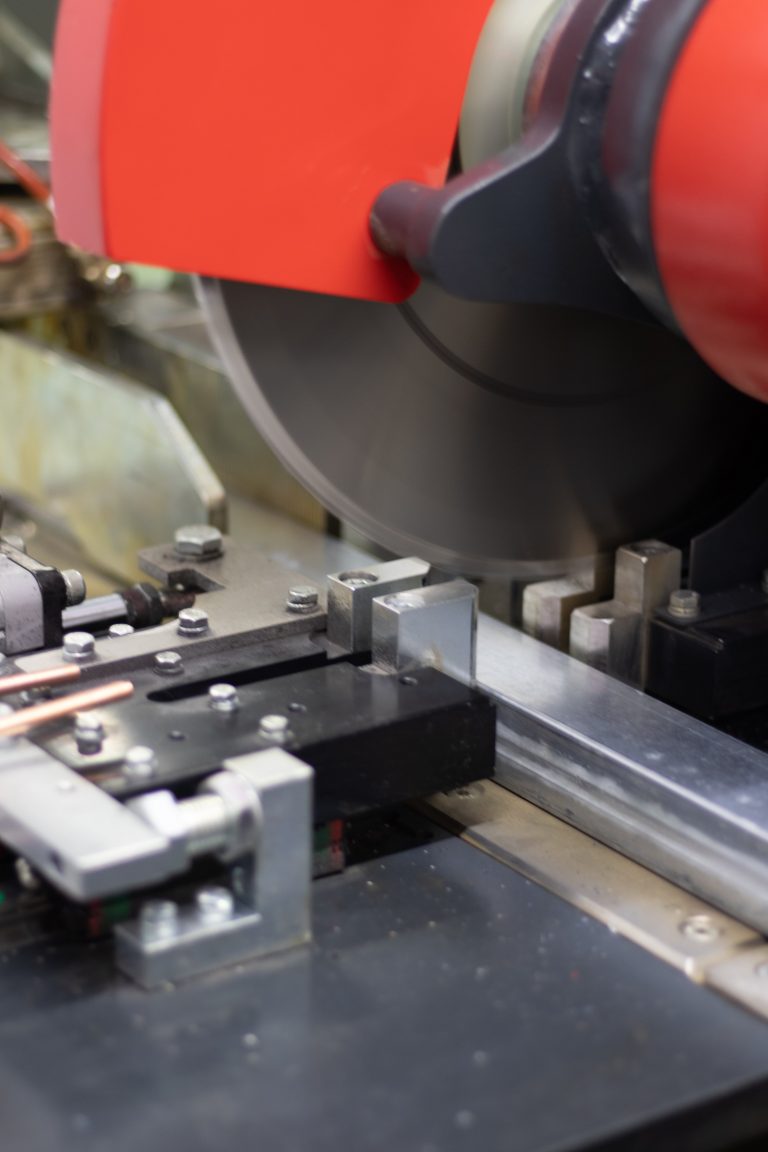

Innovative cutting and work center that combines blade cutting with plasma technology designed to carry out all the necessary work - slots, holes and cut-outs - and cutting on metal reinforcements.

A unique, intuitive and easy-to-use system is designed to significantly reduce execution times and equipped with a modern production list management software that allows you to automatically import cutting lists and synchronize production when it is online with the cutting and work centers of Graf Synergy.

5 Reasons to choose Fab Cut Plasma

Unique machine of its kind, equipped with extremely innovative technology.

Reduction of time execution: Makes cutting of reinforcements efficient.

Allows operation in synchrony with the cutting of Pvc profiles.

Automatic optimzation of cutting.

Electronic control of blade usury.

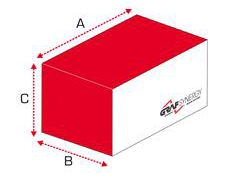

Dimensions

-

Length (A)

14.525 mm -

Width (B)

3.400 mm -

Height (C)

2.800 mm -

Weight

2.850 Kg

Details

-

Installed power

13 Kw -

Supply

400 V -

Air consumption per cycle

1.200 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Windows at 1 sash/8h*

Up to 240

* Depending on the section and type of metal to be cut.

Automatically loadable profile dimensions

-

Length

700 ÷ 6.500 mm

Workable profil dimensions

-

Width - max

80 mm -

Width - min

20 mm

-

Height - max

60 mm -

Height - min

20 mm

Loading Module

- Loading warehouse with max. capacity 9 bars.

- Loading bar system with rack pusher.

Unloading Module

- Automatic extraction and unloading of cut pieces by pneumatic extractor.

- Unloading table with belts with safety photocell.

- Max. unloading capacity 10 pieces.

On request the machine can be equipped with:

- Automatic unloading table - Width 5.000 mm.

- Vices locking with controlled axes.

- Descent blade with controlled axis.

- Blade rotation motor managed by an electronic inverter to control power consumption

- Automatic extraction and unloading of cut pieces with a second dedicated gripper on a controlled axis.

- Positioning of the unloaded profiles on a steel carpet.

- Preps module via Plasma unit.

Available Versions

Installation with only blade cutting.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA