Vertical Milling Machine

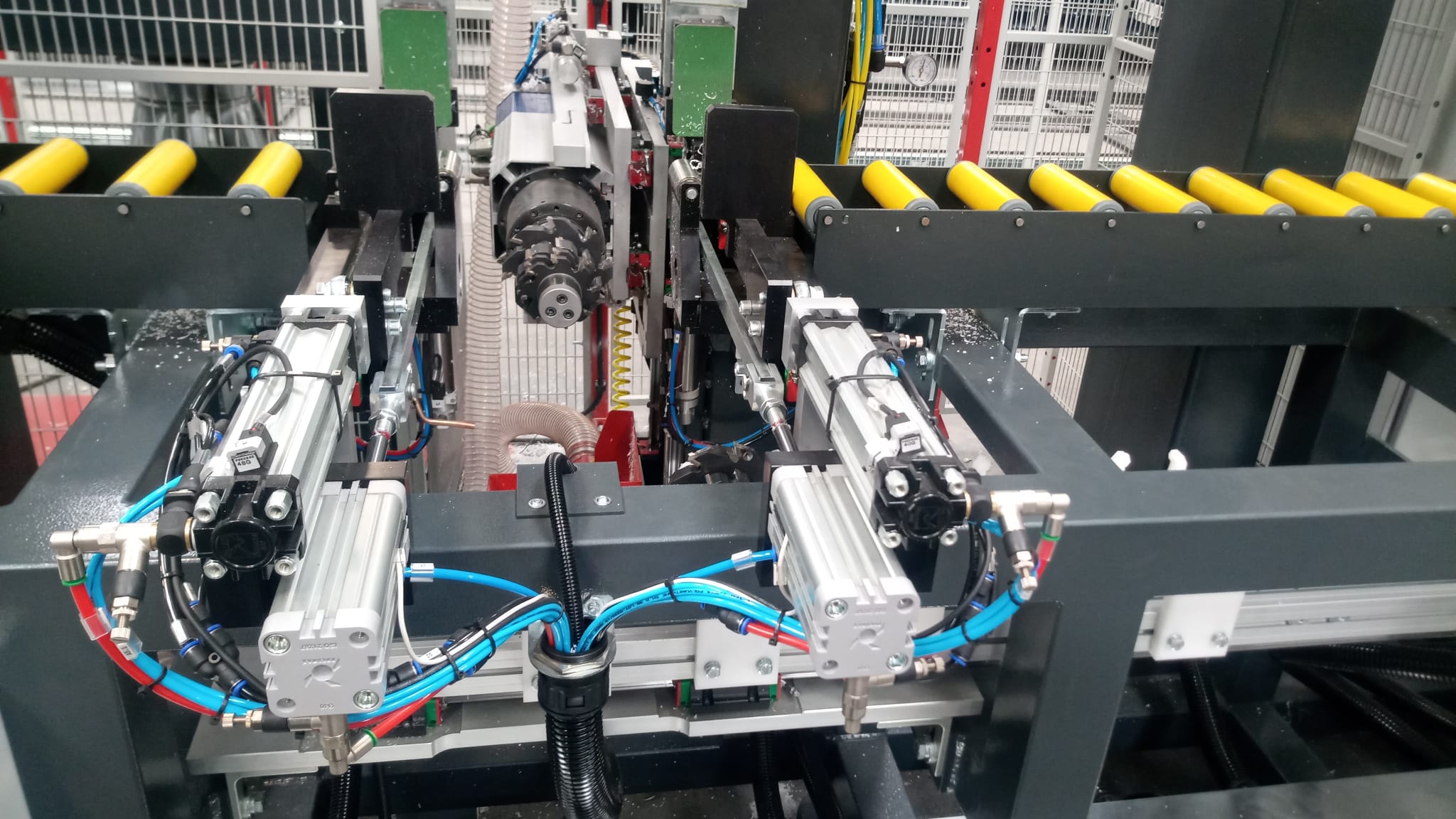

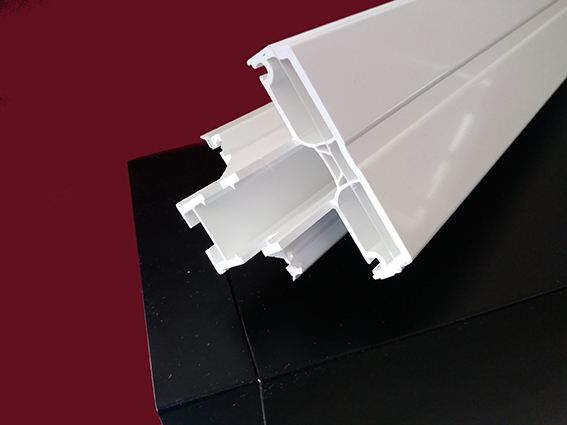

Numerically controlled automatic multi-cutter unit with 4 controlled axes designed to shape the ends of crosspieces and uprights in PVC.

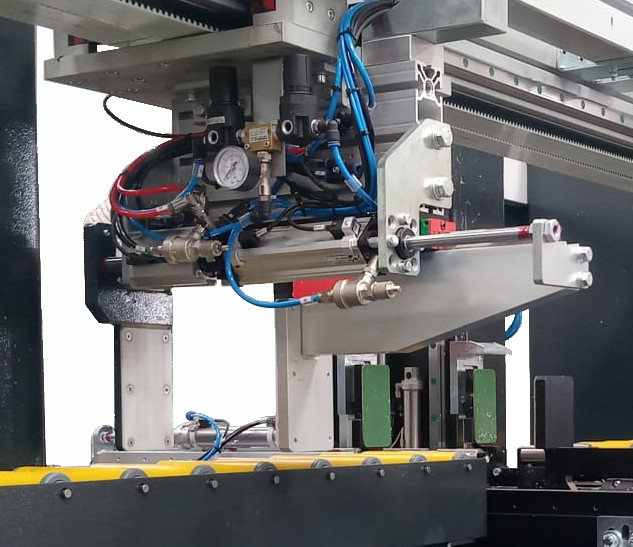

The plant is equipped with a cutter change module, connected with a servo-ventilated spindle, driven by a motorized axis that allows the adjustment of the rotation speed to perform the appropriate processing for each type of profile.

5 Reasons to choose EMV

Integration of all the workings on the beams in a single system.

Significant time and cost savings.

Warehouse containing up to 8 cutter groups with automatic quick change system.

Greater operational precision.

Double suction system.

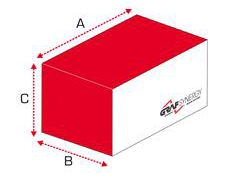

Dimensions

-

Length (A)

4.500 mm -

Width (B)

1.500 mm -

Height (C)

2.200 mm -

Weight

1.500 Kg

Details

-

Installed power

8 Kw -

Supply

400 V -

Air consumption per cycle

400 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Machined bars/8h

Depends on the machine to which it is connected

Maximum workable profile dimensions

-

Height

110 mm -

Width

280 mm

On request the machine can be equipped with:

- There are no optional elements.

Italiano

Italiano  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português  English, USA

English, USA