2 Axis Corner Cleaner Machine

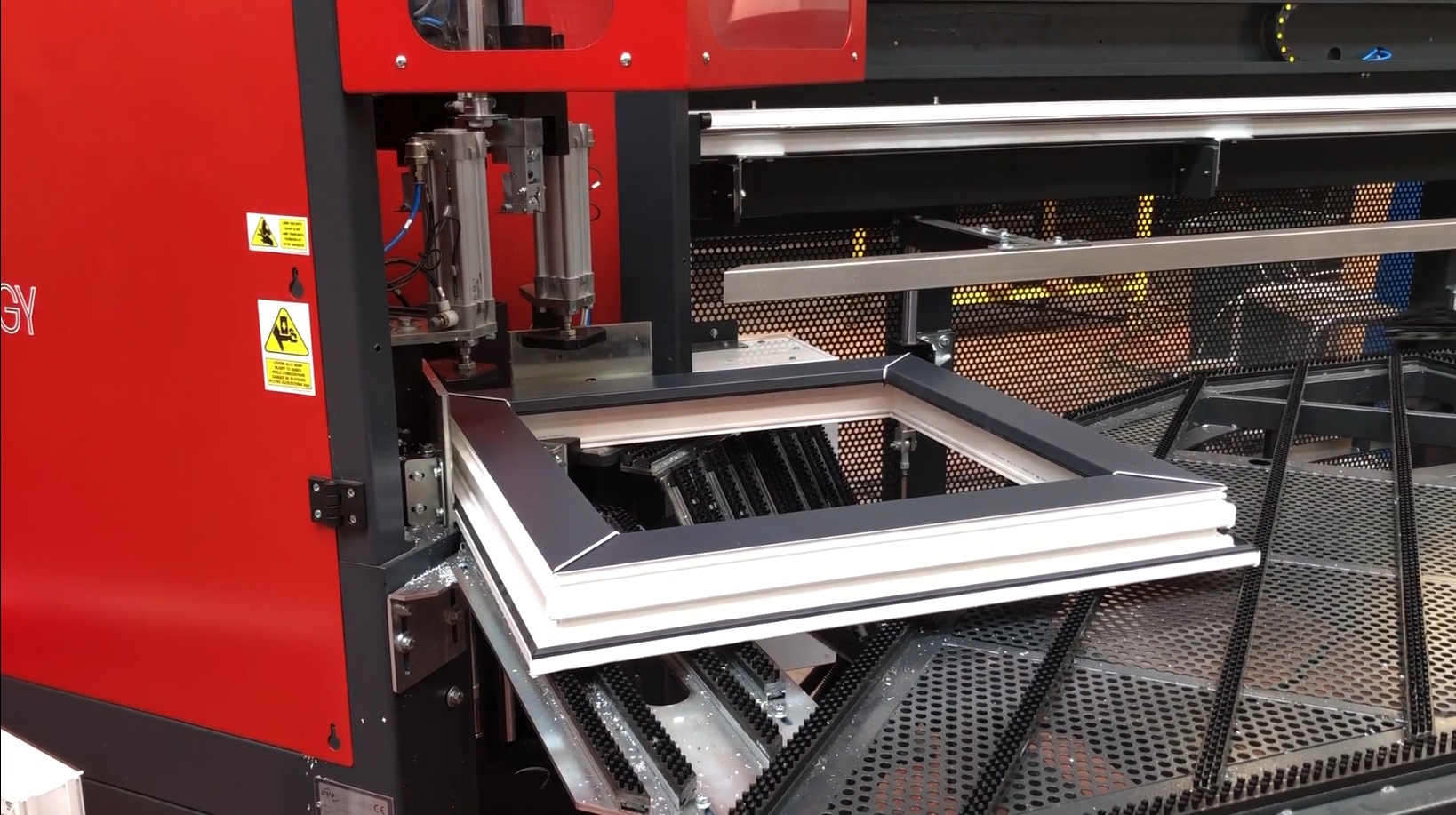

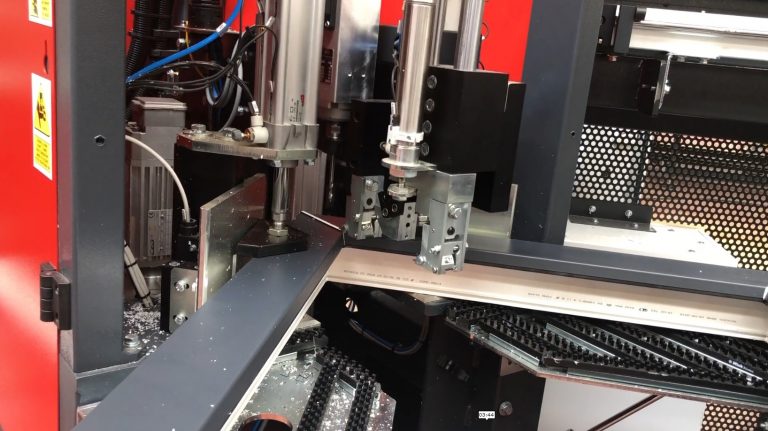

CNC corner cleaner machine with 2 controlled axes driven by brushless motors that automatically performs all the operations connected to the external cleaning of the welding bead on Vinyl profiles: performing centering, cleaning through special self-centering tools and release of the finished product.

The machine is proposed both in stand alone version and connected to an automatic piece turntable; in this case it can be put in line with a 4-head Quad welding machine.

The recognition of the panel to be treated can be done by selection on the computer supplied or by rapid reading with bar code (optional); if the machine is connected to a welding machine, it is instead done on data input of the welding machine itself.

5 Reasons to choose the WP CNC Turbo

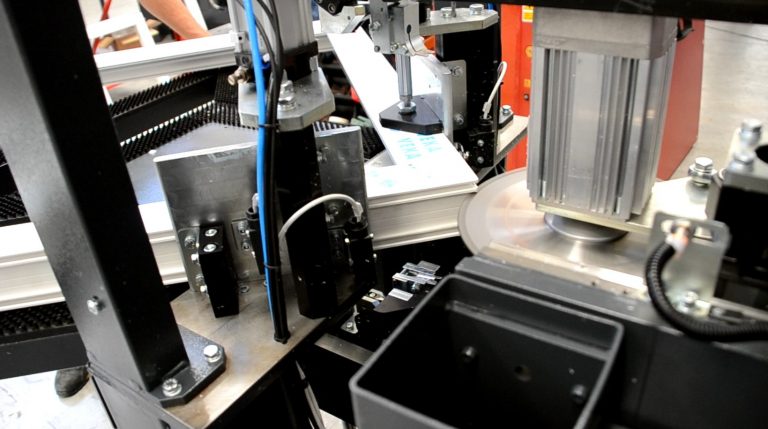

Axis positioning with brushless motors.

User Friendly: Simple cleaning program creation with loading of DXF file.

Rapid selection of the profiles to be used.

Programs acquisition with USB port and TCP-IP net.

All the work are adjustable with software.

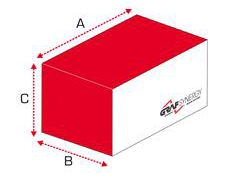

Dimensions

-

Length (A)

1.900 mm -

Width (B)

2.500 mm -

Height (C)

2.000 mm -

Weight

600 Kg

Details

-

Installed power

5.6 Kw -

Supply

400 V -

Air consumption per cycle

440 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Frames produced/8h*

Up to 200

* Stand Alone Vers.: Dependent on profile type and dimensions.

Frame Dimensions Cleanable (External)

-

Minimum*

340 x 400 mm -

Maximum

Manageable by operator

* Without rotation table.

Cleanable Profile Dimensions

Minimum

-

Height

40 mm -

Width

40 mm

Maximum

-

Height

150 mm -

Width

130 mm

Structure

Cutter disc for external corner finishing

Scratches for upper, lower and curved parts

Cutter for the removal of specific areas

Machinings

- External cleaning of the welded corner with blade

- Cleaning of external and internal profile side grooved for white profiles

- Internal and external gasket milling

- Cleaning of internal corner glazing bead area

- Cleaning of internal corner stop profile area

On request the machine can be equipped with:

- Installation stand alone (manual loading table + integral protection upper/lower).

- Rotation table with upper grip (version Left or Right) - max 2.500 x 2.500 mm.

- Rotation table with lower grip (version Left or Right) - max 2.500 x 2.500 mm.

- Internal face flat profile for colored profiles.

- External face flat profile for colored profiles.

- Second rounded knife for bevelled corners.

- Second rounded upper knife for bevelled corners.

- Upper-lower coloured knife group (complete of knives).

- Recognition profiles kit with bar code reader.

Italiano

Italiano  English

English  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português