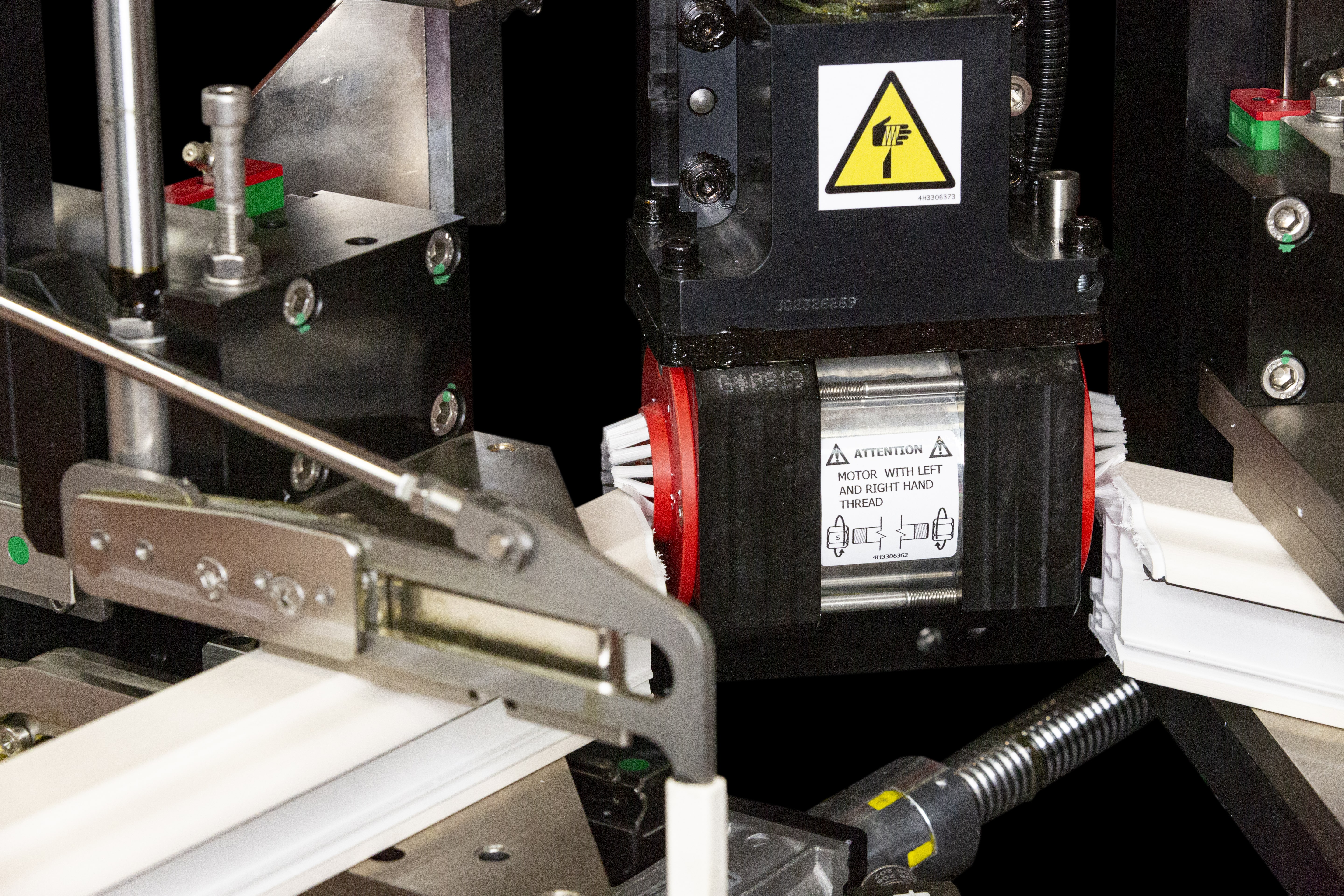

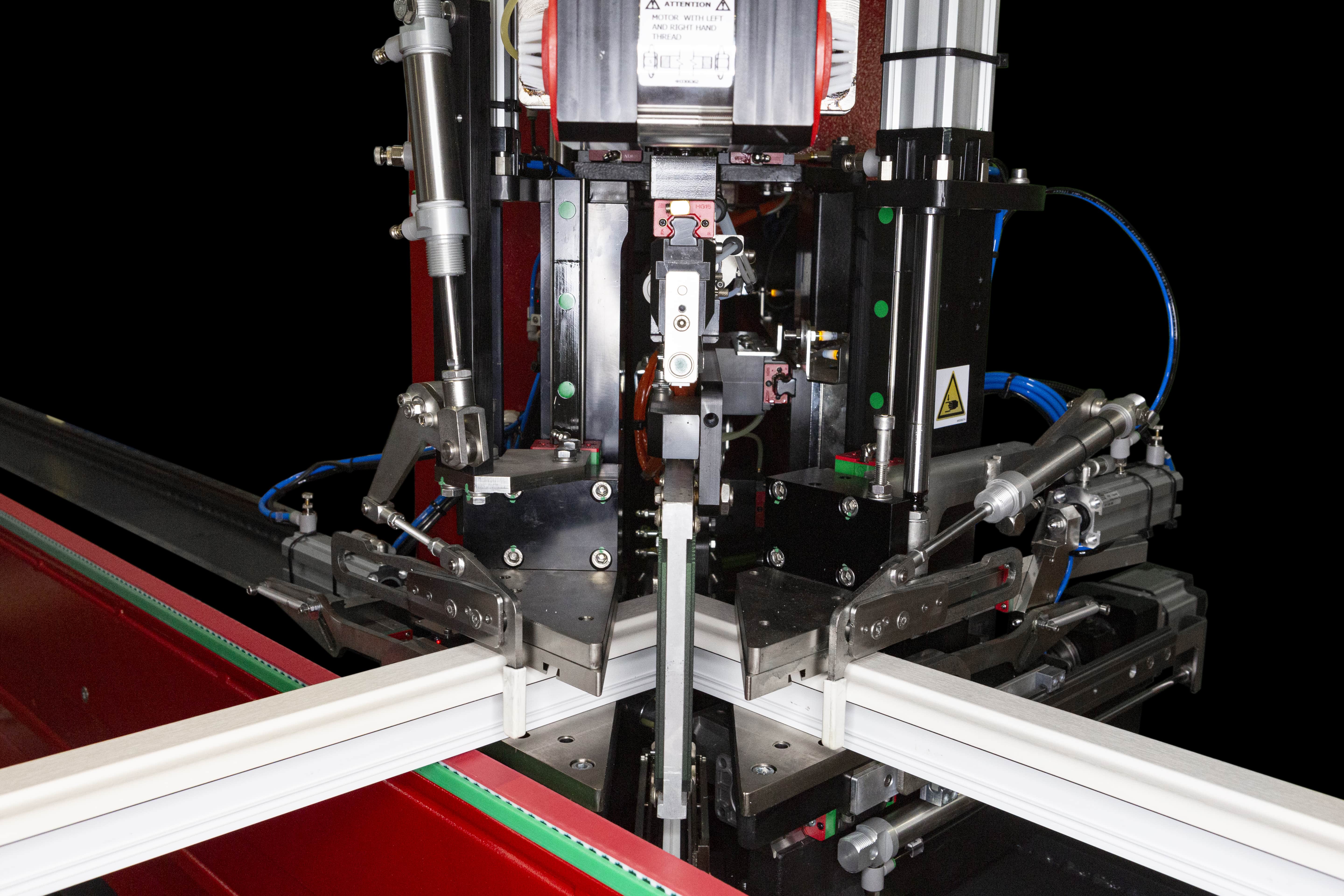

CNC 4-head welding machine

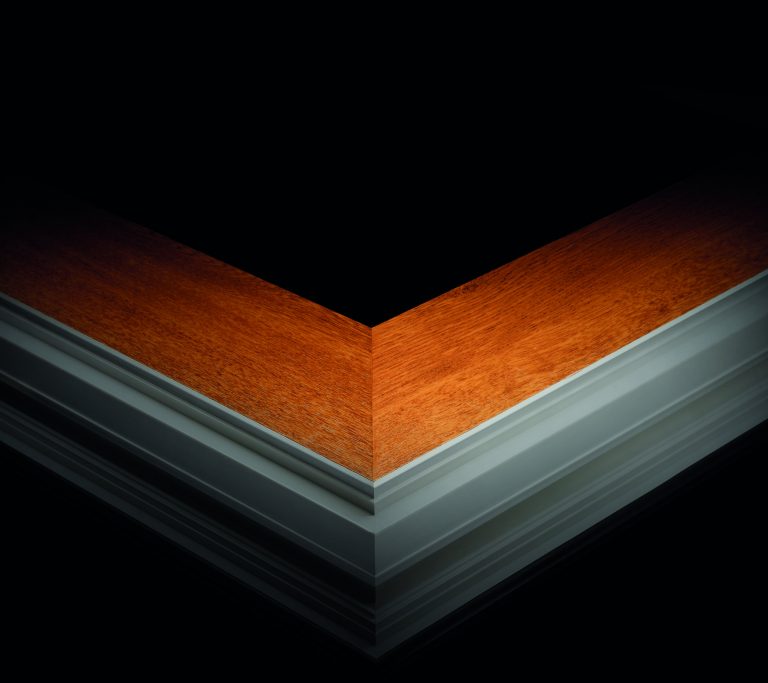

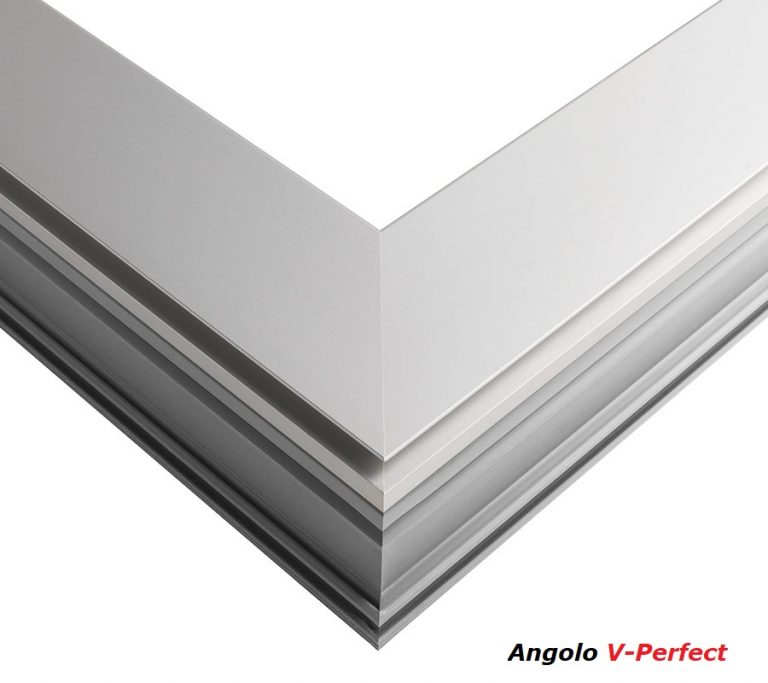

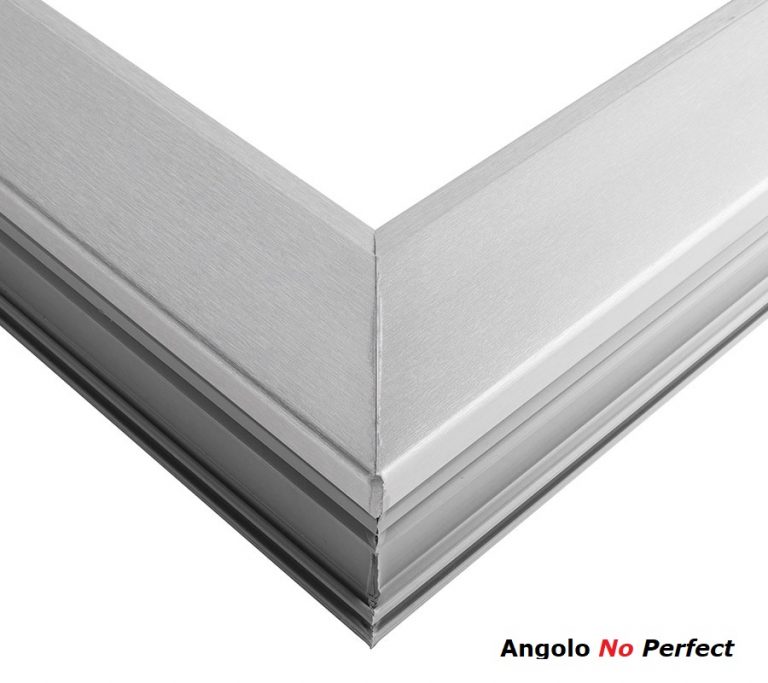

The first and only 4-head CNC welder in the world that completely eliminates the welding seam from the corner, allowing you to obtain Pvc windows of uniform quality and superior aesthetics.

Unique machine of its kind, it performs perfect welding guaranteeing absolutely flat and homogeneous surfaces also with profiles that, instead of the metal reinforcement, have inside them non-weldable products such as fiberglass, aluminum or other components.

5 Reasons to choose the SL4 FF EVO

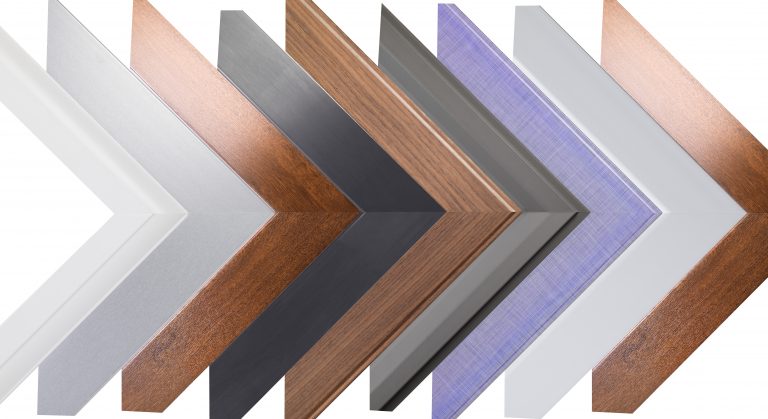

Possibility to weld profiles coated with any type of film or foil such as anodized aluminum, painted aluminum, painted Pvc, Pvc covered with natural wood or with acrylic.

Time and cost reduction: After welding, there is no need to clean or touch up.

Labor Reduction: Not having to finish the corners, only 1 operator is required to load the profiles.

Space saving: Extremely compact machine (starting from just 20 m2).

It solves the problem of profile tolerances: It has a special automatic calibration system that allows you to compensate the profiles tolerances.

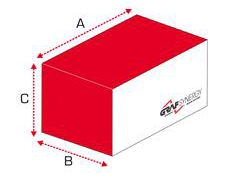

Dimensions

-

Length (A)

from 3.200 mm -

Width (B)

from 2.800 mm -

Height (C)

from 2.200 mm -

Weight

from 3.300 Kg

Note: It change according to the configuration required.

Details

-

Installed power

17 Kw -

Supply

400 V -

Air consumption per cycle

180 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Welded frames*

Up to 1/90-150 sec.

* Dependent on the types of profiles and gaskets to be processed.

Weldable Profile Dimensions

-

Height

35 ÷ 130 mm -

Width

40 ÷ 130 mm

Weldable Side Dimensions

-

Maximum

3.200 mm (on request up ot 6.000 mm) -

Minimum

370 mm

Upon request the machine can be equipped with:

- Additional heads for drilling and/or screwing of transverse.

- Different configurations for welding of different size from standard machine (3,200 x 2,800 mm).

- Mobile unloading belts with lateral movement.

- Cooling table.

- C-Welding.

- 3-sided door framing welding U (including C-welding).

- Option weldable side minimum 300 mm.

- Welding option maximum height 180 mm.

- Welding option for 140 mm wide profiles.

- Exhauster.

- Machine version according to UL/CSA.

- Software for converting imported data files.

- Production data monitoring: Control of all the data of the welded elements deriving from the optimization and manual production over time (change time of the countershims, monitoring of the working time, monitoring of the time for unloading from the cooling table).

- Electronic control system of countershims.

Italiano

Italiano  English

English  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português