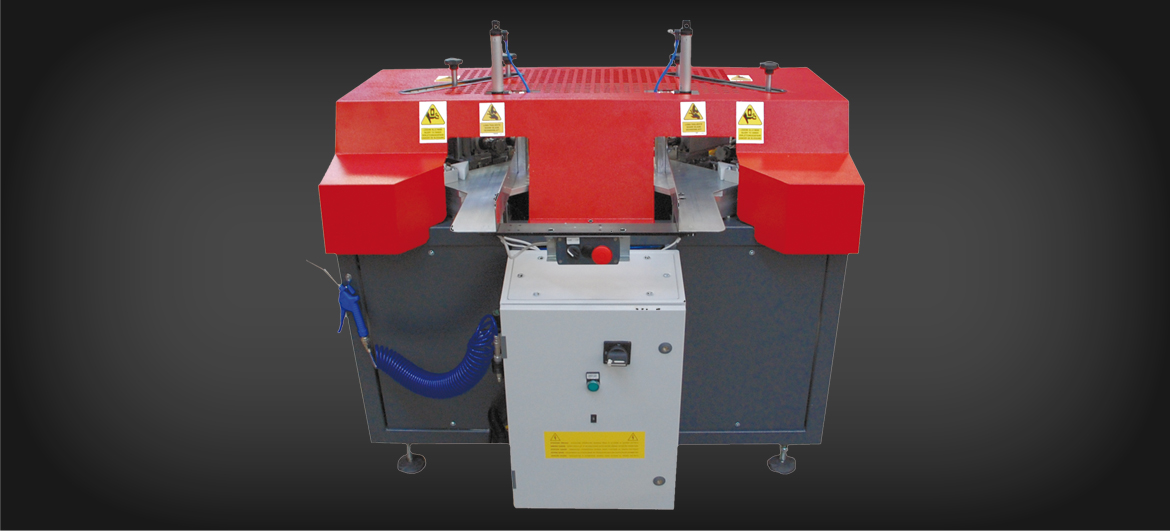

Milling machine for profiles Gaskets ends

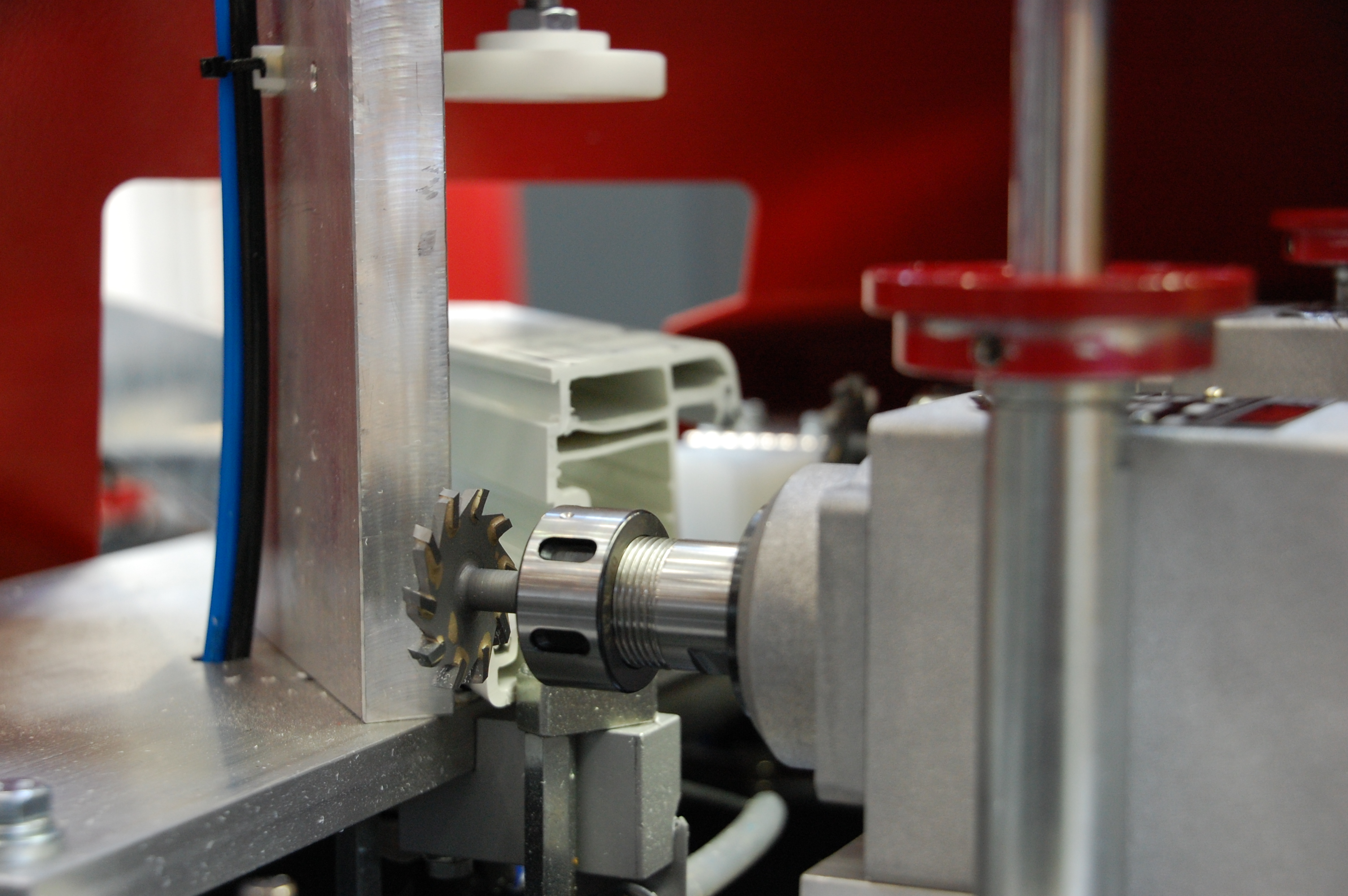

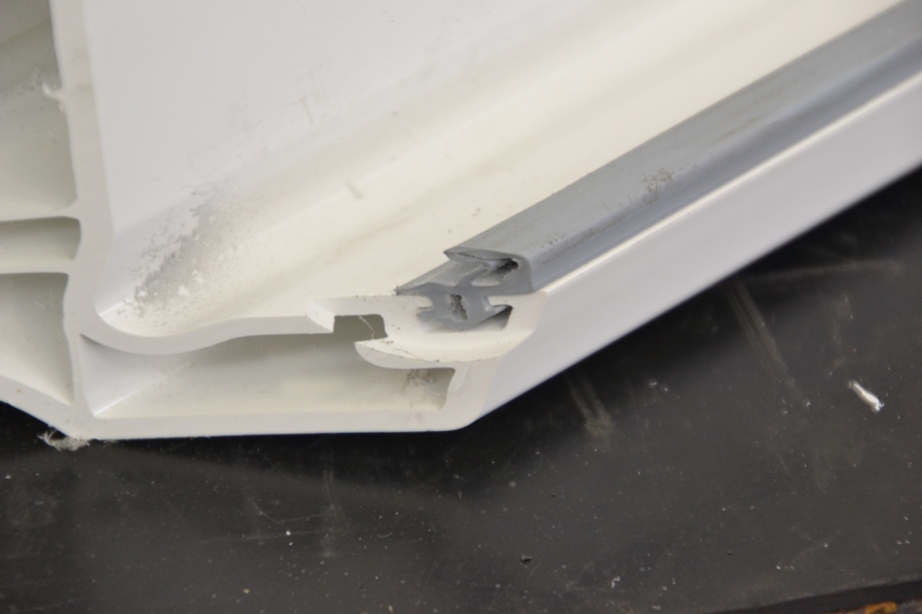

Designed and manufactured specifically to avoid the accumulation of the molten material under the gasket which, hardening during the welding process, can cause problems during the assembly of the glass.

The machine allows the simultaneous processing of 2 pieces.

Thanks to the precision of its mechanical adjustments, it is possible to obtain the exact repetition of the quantity to be removed while the manual selectors of the processing measures allow to be able to work profiles of different shapes.

5 Reasons to choose GC3-SL

It solves the problem of forcing to the mounted glass due to the accumulation of curb.

It allows a perfect closure of the door on the frame.

It allows to work also profiles with central gasket (hold at 3 gaskets).

High frequency motors without maintenance.

Possibility to work in certain times.

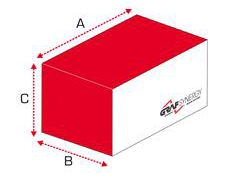

Dimensions

-

Length (A)

1.300 mm -

Width (B)

1.300 mm -

Height (C)

1.100 mm -

Weight

235 Kg

Details

-

Installed power

1.5 Kw -

Supply

230 V - Single-phase -

Air consumption per cycle

100 Nl/min -

Minimum Operating Pressure

7 bar -

Operators

1

Performance

-

Worked bars/8h

Manual Operation

Loadable profile dimensions

-

Width

40 / 130 mm -

Height

40 / 180 mm

On request the machine can be equipped with:

- There are no optional elements.

Available Variants

Version only for profiles without central gasket (Mod. GC-SL)

Italiano

Italiano  English

English  Español

Español  Français

Français  Deutsch

Deutsch  polski

polski  Português

Português